1. Kuwotcha zinthu

(1) Titaniyamu ndi ma aloyi ake oyambira sakhala olimba ndi solder yofewa.Zitsulo zodzaza ndi brazing zomwe zimagwiritsidwa ntchito popanga brazing makamaka zimaphatikizanso siliva, aluminium base, titanium base kapena titanium zirconium base.

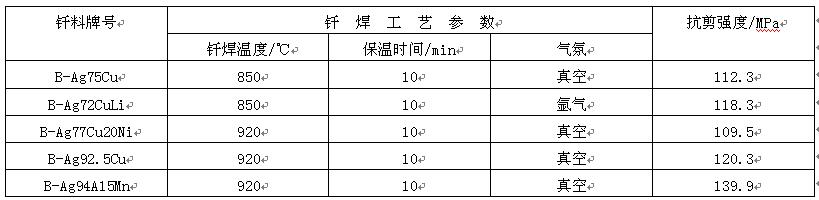

Silver zochokera solder zimagwiritsa ntchito zigawo zikuluzikulu ndi kutentha ntchito zosakwana 540 ℃.Malumikizidwe ogwiritsira ntchito siliva wangwiro amakhala ndi mphamvu zochepa, zosavuta kusweka, komanso kukana kwa dzimbiri komanso kukana kwa okosijeni.Kutentha kwamphamvu kwa Ag Cu solder ndikotsika kuposa siliva, koma kunyowa kumachepa ndi kuchuluka kwa Cu.The Ag Cu solder yokhala ndi pang'ono ya Li imatha kukonza kunyowa komanso digiri ya alloying pakati pa solder ndi chitsulo choyambira.AG Li solder ali ndi mawonekedwe otsika osungunuka komanso kuchepetsa kwambiri.Ndikoyenera kupaka titaniyamu ndi ma aloyi a titaniyamu mumlengalenga woteteza.Komabe, vacuum brazing imayipitsa ng'anjoyo chifukwa cha evaporation ya Li.Ag-5al- (0.5 ~ 1.0) Mn filler zitsulo ndiye chitsulo chomwe chimakondedwa pazigawo zopyapyala zokhala ndi mipanda ya titaniyamu.Mgwirizano wa brazed uli ndi okosijeni wabwino komanso kukana dzimbiri.Kuthekera kwa kukameta ubweya wa titaniyamu ndi titaniyamu aloyi olumikizana ndi zitsulo zomangika ndi silver base filler zikuwonetsedwa mu Table 12.

Table 12 brazing process magawo ndi mphamvu yolumikizana ya titaniyamu ndi titaniyamu aloyi

Kutentha kwachitsulo kwa aluminiyamu yochokera ku solder ndi otsika, zomwe sizingabweretse kusinthika kwa titaniyamu alloy β Phase kumachepetsa zofunikira pakusankhidwa kwa zida zopangira brazing ndi zomangamanga.Kuyanjana pakati pa zitsulo zodzaza ndi zitsulo zoyambira ndizochepa, ndipo kusungunuka ndi kufalikira sikukuwonekera, koma pulasitiki ya zitsulo zodzaza ndi zabwino, ndipo n'zosavuta kugudubuza zitsulo zodzaza ndi zitsulo pamodzi, kotero zimakhala bwino. abwino kwambiri pakuwotcha titaniyamu alloy radiator, kapangidwe ka zisa ndi kapangidwe ka laminate.

Titaniyamu zochokera ku titaniyamu kapena titaniyamu zirconium zochokera ku fluxes nthawi zambiri zimakhala ndi Cu, Ni ndi zinthu zina, zomwe zimatha kufalikira mwachangu mu matrix ndikuchitapo kanthu ndi titaniyamu pakuwomba, zomwe zimapangitsa kuti matrix adzimbiri komanso kupanga wosanjikiza.Choncho, kutentha kwa brazing ndi nthawi yogwira kuyenera kuyendetsedwa mosamalitsa panthawi yowotcha, ndipo sayenera kugwiritsidwa ntchito pomanga nyumba zokhala ndi mipanda yopyapyala momwe zingathere.B-ti48zr48be ndi solder wamba wa Ti Zr.Ili ndi kunyowa bwino kwa titaniyamu, ndipo chitsulo choyambira sichikhala ndi chizolowezi chakukula kwambewu panthawi yowotcha.

(2) Brazing filler zitsulo za zirconium ndi maziko a alloys brazing zirconium ndi ma alloys oyambira makamaka amaphatikiza b-zr50ag50, b-zr76sn24, b-zr95be5, ndi zina zotere, zomwe zimagwiritsidwa ntchito kwambiri pakuwotcha kwa zirconium alloy mapaipi a zida zanyukiliya.

(3) Kutentha kwamadzi ndi chitetezo cha titaniyamu, zirconium ndi ma alloys oyambira amatha kupeza zotsatira zokhutiritsa mu vacuum ndi inert atmosphere (helium ndi argon).Kuyeretsa kwakukulu kwa argon kudzagwiritsidwa ntchito pazitsulo zotetezedwa ndi argon, ndipo mame ayenera kukhala -54 ℃ kapena pansi.Flux yapadera yokhala ndi fluoride ndi chloride yachitsulo Na, K ndi Li iyenera kugwiritsidwa ntchito poyatsa moto.

2. Zipangizo zamakono

Pamaso pa brazing, pamwamba ayenera kutsukidwa bwino, degreased ndi okusayidi filimu kuchotsedwa.Filimu yokhuthala ya oxide iyenera kuchotsedwa ndi makina, njira yophulitsira mchenga kapena njira yosambitsira mchere wosungunuka.Filimu yopyapyala ya oxide imatha kuthetsedwa mu yankho lomwe lili ndi 20% ~ 40% nitric acid ndi 2% hydrofluoric acid.

Ti, Zr ndi ma alloys awo saloledwa kukhudza malo olowa ndi mpweya pakuwotcha kwamoto.Brazing ikhoza kuchitidwa pansi pa chitetezo cha vacuum kapena gasi wa inert.Kutenthetsa kwafupipafupi kwambiri kapena kutentha muchitetezo kungagwiritsidwe ntchito.Kutentha kwa induction ndiye njira yabwino kwambiri yazigawo zing'onozing'ono zofananira, pomwe kuwotcha mu ng'anjo kumakhala kopindulitsa pazinthu zazikulu komanso zovuta.

Ni Cr, W, Mo, Ta ndi zida zina zidzasankhidwa ngati zinthu zotenthetsera za Ti, Zr ndi ma alloys awo.Zida zokhala ndi graphite yowonekera ngati zinthu zotenthetsera siziyenera kugwiritsidwa ntchito kupewa kuipitsidwa kwa kaboni.Zopangira brazing ziyenera kupangidwa ndi zida zokhala ndi mphamvu zotentha kwambiri, zofananira zowonjezera kutentha kwa Ti kapena Zr, komanso kutsika kocheperako ndi chitsulo choyambira.

Nthawi yotumiza: Jun-13-2022