1. Kulimba mtima

The brazing katundu wa aluminiyamu ndi zitsulo zotayidwa aloyi ndi osauka, makamaka chifukwa okusayidi filimu pamwamba ndi zovuta kuchotsa.Aluminiyamu imagwirizana kwambiri ndi mpweya.Ndiosavuta kupanga wandiweyani, wokhazikika komanso wapamwamba wosungunuka wa oxide filimu Al2O3 pamtunda.Panthawi imodzimodziyo, zotayira za aluminium zomwe zili ndi magnesium zidzapanganso filimu yokhazikika ya oxide MgO.Iwo adzalepheretsa kwambiri kunyowetsa ndi kufalikira kwa solder.Ndipo zovuta kuchotsa.Pa brazing, njira yowotchera imatha kuchitidwa kokha ndi flux yoyenera.

Kachiwiri, ntchito ya aluminiyamu ndi aluminium alloy brazing ndizovuta.Kusungunuka kwa aluminiyamu ndi aloyi ya aluminiyamu sikusiyana kwambiri ndi zitsulo zopangira zitsulo zomwe zimagwiritsidwa ntchito.Kutentha kosankha kwa brazing ndi kochepa kwambiri.Kuwongolera pang'ono kosayenera kwa kutentha kumakhala kosavuta kuyambitsa kutentha kapena kusungunuka kwazitsulo zapansi, zomwe zimapangitsa kuti zitsulo zikhale zovuta.Ma aluminiyamu ena omwe amalimbikitsidwa ndi chithandizo cha kutentha amayambitsanso zochitika zofewa monga kukalamba kapena kuzizira chifukwa cha kutentha kwa brazing, zomwe zimachepetsa mphamvu zamagulu olimba.Panthawi yoyaka moto, zimakhala zovuta kuweruza kutentha chifukwa mtundu wa aluminiyamu susintha panthawi yotentha, zomwe zimawonjezeranso zofunikira pa ntchito ya woyendetsa.

Kuphatikiza apo, kukana kwa dzimbiri kwa aluminiyamu ndi aluminiyumu aloyi brazed zolumikizira zimakhudzidwa mosavuta ndi zitsulo zodzaza ndi ma fluxes.Mphamvu ya electrode ya aluminiyamu ndi aloyi ya aluminiyamu ndi yosiyana kwambiri ndi ya solder, zomwe zimachepetsa kukana kwa dzimbiri kwa olowa, makamaka pazitsulo zofewa.Kuphatikiza apo, ma fluxes ambiri omwe amagwiritsidwa ntchito pakuwotcha kwa aluminiyamu ndi ma aluminiyamu aloyi amakhala ndi dzimbiri lamphamvu.Ngakhale atatsukidwa pambuyo pa brazing, chikoka cha fluxes pa dzimbiri kukaniza mafupa sikudzathetsedwa kwathunthu.

2. Kuwotcha zinthu

(1) Kuwotcha kwa aluminiyamu ndi ma aloyi a aluminiyamu ndi njira yosagwiritsidwa ntchito kawirikawiri, chifukwa kapangidwe kake ndi ma elekitirodi a zitsulo zomangira zitsulo ndi zitsulo zoyambira ndizosiyana kwambiri, zomwe ndizosavuta kuyambitsa dzimbiri la electrochemical pamgwirizano.The solder yofewa makamaka utenga solder zinc zochokera ndi malata lead solder, amene akhoza kugawidwa otsika kutentha solder (150 ~ 260 ℃), sing'anga kutentha solder (260 ~ 370 ℃) ndi kutentha solder (370 ~ 430 ℃) malinga ndi kutentha osiyanasiyana.Pamene tini lead solder ikugwiritsidwa ntchito ndipo mkuwa kapena faifi tambala atakutidwa pamwamba pa aluminiyamu pamwamba kuti aziwotcha, dzimbiri panjira yolumikizirana zitha kupewedwa, kuti apititse patsogolo kukana kwa dzimbiri kwa olowa.

Kuwotcha kwa aluminiyamu ndi ma aloyi a aluminiyamu kumagwiritsidwa ntchito kwambiri, monga kalozera wazosefera, evaporator, radiator ndi zinthu zina.Zitsulo zokha za aluminiyamu zomwe zingagwiritsidwe ntchito popangira ma aluminiyamu ndi ma aloyi a aluminiyamu, zomwe zitsulo zotayidwa za aluminium silicon filler ndizomwe zimagwiritsidwa ntchito kwambiri.Kukula kwachindunji ndi mphamvu yakumeta ubweya wa zolumikizira zolimba zikuwonetsedwa mu Gulu 8 ndi tebulo 9 motsatana.Komabe, malo osungunuka a solder awa ali pafupi ndi zitsulo zoyambira, choncho kutentha kwa kutentha kuyenera kuyendetsedwa mosamalitsa komanso molondola panthawi yachitsulo kuti zisawonongeke kapena kusungunuka kwazitsulo.

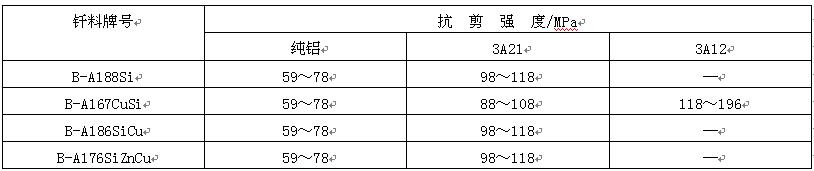

Table 8 kuchuluka kwa zitsulo zodzaza ndi zitsulo za aluminiyamu ndi ma aluminiyamu

Table 9 mphamvu yakumeta ubweya wa aluminiyamu ndi ma aluminiyamu aloyi zolumikizira zokongoletsedwa ndi aluminiyamu silicon filler zitsulo

Aluminium silicon solder nthawi zambiri imaperekedwa mu mawonekedwe a ufa, phala, waya kapena pepala.Nthawi zina, mbale zophatikizika zokhala ndi aluminiyamu monga pachimake ndi aluminium silicon solder monga zomangira zimagwiritsidwa ntchito.Mtundu uwu wa solder composite plate umapangidwa ndi njira ya hydraulic ndipo nthawi zambiri imagwiritsidwa ntchito ngati gawo la zigawo za brazing.Panthawi yowotcha, chitsulo chodzaza ndi brazing pa mbale yophatikizika chimasungunuka ndikuyenderera pansi pakuchita kwa capillary ndi mphamvu yokoka kuti mudzaze kusiyana.

(2) Flux ndi kutchingira gasi kwa aluminiyamu ndi aluminium alloy brazing, flux yapadera imagwiritsidwa ntchito kuchotsa filimuyo.organic flux yotengera triethanolamine, monga fs204, imagwiritsidwa ntchito ndi solder yofewa yotsika kutentha.Ubwino wa flux uwu ndikuti umakhala ndi mphamvu zochepa zowononga pazitsulo zoyambira, koma zidzatulutsa mpweya wambiri, womwe ungakhudze kunyowa ndi kutsekemera kwa solder.The reactive flux yochokera ku zinc chloride, monga fs203 ndi fs220a, imagwiritsidwa ntchito ndi kutentha kwapakatikati komanso kutentha kwambiri solder yofewa.The reactive flux ndi yowononga kwambiri, ndipo zotsalira zake ziyenera kuchotsedwa pambuyo powotcha.

Pakadali pano, kuwotcha kwa aluminiyamu ndi ma aloyi a aluminiyamu kumayendetsedwabe ndi kuchotsa filimu yotulutsa.Kuthamanga kwa brazing komwe kumagwiritsidwa ntchito kumaphatikizapo chloride based flux ndi fluoride based flux.Chloride yochokera ku flux imatha kuchotsa filimu ya oxide ndi fluidity yabwino, koma imawononga kwambiri zitsulo zam'munsi.Zotsalira zake ziyenera kuchotsedwa kwathunthu pambuyo pakuwotcha.Fluoride based flux ndi mtundu watsopano wa flux, womwe uli ndi zotsatira zabwino zochotsa filimu ndipo palibe dzimbiri pazitsulo zoyambira.Komabe, ili ndi malo osungunuka kwambiri komanso osasunthika bwino, ndipo ingagwiritsidwe ntchito ndi aluminium solder ya silicon.

Mukawotcha aluminiyamu ndi ma aluminiyamu aloyi, vacuum, ndale kapena mlengalenga wa inert nthawi zambiri amagwiritsidwa ntchito.Mukamagwiritsa ntchito vacuum brazing, digiri ya vacuum iyenera kufika pa dongosolo la 10-3pa.Akagwiritsidwa ntchito poteteza nayitrogeni kapena mpweya wa argon, chiyero chake chiyenera kukhala chokwera kwambiri, ndipo mame ayenera kukhala otsika kuposa -40 ℃.

3. Ukadaulo wa brazing

Kuwotcha kwa aluminiyamu ndi ma aloyi a aluminiyamu kumakhala ndi zofunika kwambiri pakuyeretsa pamwamba pa workpiece.Kuti mupeze mtundu wabwino, utoto wamafuta ndi filimu ya oxide pamtunda uyenera kuchotsedwa musanawombe.Chotsani banga la mafuta pamtunda ndi Na2CO3 yankho lamadzimadzi pa kutentha kwa 60 ~ 70 ℃ kwa 5 ~ 10min, ndiyeno muzimutsuka ndi madzi oyera;The pamwamba okusayidi filimu akhoza kuchotsedwa ndi etching ndi NaOH amadzimadzi njira pa kutentha kwa 20 ~ 40 ℃ kwa 2 ~ 4min, ndiyeno osambitsidwa ndi madzi otentha;Pambuyo kuchotsa banga mafuta ndi okusayidi filimu padziko, workpiece adzakhala mankhwala ndi HNO3 amadzimadzi njira gloss kwa 2 ~ 5min, ndiye kutsukidwa mu madzi othamanga ndipo potsiriza zouma.Chogwiritsira ntchito chogwiritsidwa ntchito ndi njirazi sichidzakhudzidwa kapena kuipitsidwa ndi dothi lina, ndipo chiyenera kutsekedwa mkati mwa 6 ~ 8h.Ndi bwino kuumitsa nthawi yomweyo ngati n'kotheka.

Njira zowotchera za aluminiyumu ndi ma aluminiyamu aloyi makamaka zimaphatikizanso kuyaka kwamoto, kuwotcha kwachitsulo ndi kuwotcha kwa ng'anjo.Njirazi nthawi zambiri zimagwiritsa ntchito flux mu brazing, ndipo zimakhala ndi zofunika kwambiri pa kutentha kwa kutentha ndi nthawi yogwira.Panthawi yowotcha moto ndi chitsulo chowotchera, pewani kutenthetsa madziwo ndi gwero la kutentha kuti musatenthedwe ndi kulephera.Popeza aluminiyamu imatha kusungunuka mu solder yofewa yokhala ndi zinc wambiri, kutentha kuyenera kuyimitsidwa pomwe olowa apangidwa kuti apewe dzimbiri zachitsulo.Nthawi zina, kuwomba kwa aluminiyamu ndi ma aluminiyamu aloyi nthawi zina sagwiritsa ntchito flux, koma amagwiritsa ntchito njira za ultrasonic kapena scraping kuchotsa filimuyo.Mukamagwiritsa ntchito scraping kuti muchotse filimuyo kuti muwotche, choyamba tenthetsani chipangizocho kuti chitenthe kutentha, kenaka pukutani mbali yowotchera ndi mapeto a ndodo ya solder (kapena chida chosula).Pamene akuswa pamwamba oxide filimu, mapeto a solder adzasungunuka ndi kunyowetsa m'munsi zitsulo.

Njira zopangira ma aluminiyamu ndi ma aloyi a aluminiyumu makamaka zimaphatikizanso kuyatsa moto, kuwotcha kwa ng'anjo, kuviika kwa dip brazing, vacuum brazing ndi kutchingira kwa gasi.Kuwotcha kwamoto kumagwiritsidwa ntchito kwambiri popanga tinthu tating'onoting'ono komanso kupanga chidutswa chimodzi.Pofuna kupewa kulephera kwa flux chifukwa cha kukhudzana pakati zonyansa mu acetylene ndi flux ntchito oxyacetylene lawi, ndi koyenera kugwiritsa ntchito mafuta wothinikizidwa mpweya lawi ndi reducibility pang`ono kupewa makutidwe ndi okosijeni wa m`munsi zitsulo.Pakuwotcha kwachindunji, chiwombankhanga chachitsulo ndi zitsulo zodzaza zimatha kuikidwa pamalo otsekemera pasadakhale ndikutenthedwa nthawi yomweyo ndi chogwirira ntchito;The workpiece amathanso kutenthedwa ndi kutentha kwa brazing poyamba, ndiyeno solder yoviikidwa ndi flux ikhoza kutumizidwa kumalo otsekemera;Pambuyo posungunuka ndi zitsulo zodzaza, moto woyaka moto umachotsedwa pang'onopang'ono pambuyo poti zitsulo zodzaza zimadzaza mofanana.

Mukawotcha aluminiyamu ndi aloyi mu ng'anjo ya mpweya, chitsulo chodzaza ndi brazing chiyenera kukhazikitsidwa, ndipo chitsulo chosungunula chimasungunuka m'madzi osungunuka kuti chikonze yankho lakuda ndi 50% ~ 75%, ndiyeno wokutidwa kapena kupopera. pamwamba pamoto.Kuchuluka koyenera kwa ufa wa brazing flux kumathanso kuphimbidwa pazitsulo zodzaza ndi brazing ndi brazing pamwamba, ndiyeno chowotcherera chosonkhanitsidwa chidzayikidwa mu ng'anjo yowotcha.Pofuna kupewa zitsulo zoyambira kuti zisatenthe kapena kusungunuka, kutentha kwa kutentha kuyenera kuyendetsedwa mosamalitsa.

Phala kapena zojambulazo zimagwiritsidwa ntchito poyika brazing ya aluminiyamu ndi ma aloyi a aluminiyamu.Chogwiritsira ntchito chosonkhanitsidwa chiyenera kutenthedwa chisanayambe kutentha kuti kutentha kwake kukhale pafupi ndi kutentha kwa kutentha, ndiyeno kumizidwa mu brazing flux kwa brazing.Panthawi ya brazing, kutentha kwa brazing ndi nthawi ya brazing ziyenera kuyendetsedwa bwino.Ngati kutentha kuli kwakukulu, chitsulo choyambira chimakhala chosavuta kusungunuka ndipo solder ndi yosavuta kutayika;Ngati kutentha kuli kochepa kwambiri, solder sichisungunuka mokwanira, ndipo kutentha kwachitsulo kumachepa.Kutentha kwa brazing kumatsimikiziridwa molingana ndi mtundu ndi kukula kwa chitsulo choyambira, kapangidwe kake ndi malo osungunuka a zitsulo zodzaza, ndipo nthawi zambiri zimakhala pakati pa kutentha kwa liquidus kwa chitsulo chodzaza ndi kutentha kwa solidus kwachitsulo choyambira.Kuviika nthawi ya workpiece mu kusamba flux ayenera kuonetsetsa kuti solder akhoza kusungunuka kwathunthu ndi kutuluka, ndipo nthawi yothandizira sayenera kukhala yaitali kwambiri.Kupanda kutero, chinthu cha silicon mu solder chikhoza kufalikira muzitsulo zoyambira, kupangitsa chitsulo chapansi pafupi ndi msoko kukhala brittle.

Mu vacuum brazing ya aluminiyamu ndi zitsulo zotayidwa, zida zogwiritsira ntchito zitsulo zimagwiritsidwa ntchito kusintha filimu ya oxide ya aluminiyamu ndikuonetsetsa kuti kunyowetsa ndi kufalikira kwa solder.Magnesium angagwiritsidwe ntchito mwachindunji pa workpiece mu mawonekedwe a tinthu tating'onoting'ono, kapena kulowetsedwa mu zone brazing mu mawonekedwe nthunzi, kapena magnesium akhoza kuwonjezeredwa kwa zotayidwa pakachitsulo solder monga aloyi chinthu.Kwa workpiece yokhala ndi dongosolo lovuta, pofuna kuonetsetsa kuti mpweya wa magnesium ukugwira ntchito pazitsulo zoyambira ndikuwongolera khalidwe lachitsulo, njira zotetezera m'deralo zimatengedwa nthawi zambiri, ndiko kuti, chogwirira ntchito chimayikidwa choyamba mubokosi lachitsulo chosapanga dzimbiri (kawirikawiri). lotchedwa process box), ndiyeno nkumayikidwa mu ng'anjo ya vacuum yowotchera moto.Vacuum Brazed Aluminium ndi ma aluminiyumu aloyi zolumikizira zimakhala zosalala pamwamba komanso zolumikizana zolimba zolimba, ndipo siziyenera kutsukidwa pambuyo pakuwotcha;Komabe, zida za vacuum brazing ndi zokwera mtengo, ndipo nthunzi ya magnesium imaipitsa ng'anjoyo kwambiri, motero iyenera kutsukidwa ndikusungidwa pafupipafupi.

Mukawotcha ma aluminiyamu ndi ma aloyi a aluminiyumu m'malo osalowerera kapena osalowerera, magnesium activator kapena flux ingagwiritsidwe ntchito kuchotsa filimuyo.Pamene magnesium activator imagwiritsidwa ntchito kuchotsa filimuyo, kuchuluka kwa magnesiamu komwe kumafunikira kumakhala kotsika kwambiri kuposa kwa vacuum brazing.Nthawi zambiri, w (mg) ndi pafupifupi 0.2% ~ 0.5%.Pamene magnesium ili pamwamba, ubwino wa mgwirizanowo udzachepetsedwa.NOCOLOK brazing njira yogwiritsira ntchito fluoride flux ndi chitetezo cha nayitrogeni ndi njira yatsopano yomwe yapangidwa mwachangu m'zaka zaposachedwa.Popeza zotsalira za fluoride flux sizimamwa chinyezi ndipo sizimawononga aluminiyamu, njira yochotsera zotsalira za flux pambuyo pakuwotcha imatha kuchotsedwa.Motetezedwa ndi nayitrogeni, kuchuluka kwa fluoride kokha kumafunika kuphimbidwa, zitsulo zodzaza zimatha kunyowetsa chitsulo choyambira, ndipo ndikosavuta kupeza zolumikizira zapamwamba kwambiri.Pakalipano, njira iyi ya NOCOLOK ya brazing yakhala ikugwiritsidwa ntchito popanga ma radiator a aluminiyamu ndi zigawo zina.

Kwa aluminiyamu ndi aloyi ya aluminiyumu yolumikizidwa ndi flux kupatula fluoride flux, zotsalira za flux ziyenera kuchotsedwa kwathunthu pambuyo pakuwotcha.Zotsalira za organic brazing flux za aluminiyamu zimatha kutsukidwa ndi njira za organic monga methanol ndi trichlorethylene, zopanda mphamvu ndi sodium hydroxide aqueous solution, ndipo pomaliza zimatsukidwa ndi madzi otentha ndi ozizira.Chloride ndi yotsalira ya brazing flux ya aluminiyamu, yomwe imatha kuchotsedwa motsatira njira zotsatirazi;Choyamba, zilowerereni m'madzi otentha pa 60 ~ 80 ℃ kwa 10min, yeretsani mosamala zotsalira pamagulu osakanikirana ndi burashi, ndikuyeretsani ndi madzi ozizira;Kenako zilowerereni mu 15% nitric acid amadzimadzi njira 30min, ndipo potsiriza muzimutsuka ndi madzi ozizira.

Nthawi yotumiza: Jun-13-2022