1. Kuwotcha zinthu

(1)Kuwotcha kwachitsulo cha carbon ndi chitsulo chochepa cha alloy kumaphatikizapo kuwomba kofewa komanso kuwomba mwamphamvu.Chogulitsa chomwe chimagwiritsidwa ntchito kwambiri mu soldering yofewa ndi tini lead solder.Kunyowa kwa solder iyi kuchitsulo kumawonjezeka ndi kuchuluka kwa malata, kotero solder yokhala ndi malata apamwamba iyenera kugwiritsidwa ntchito posindikiza mafupa.Fesn2 intermetallic pawiri wosanjikiza akhoza kupangidwa pa mawonekedwe pakati malata ndi zitsulo mu malata lead solder.Pofuna kupewa kupangika kwapawiri mu gawo ili, kutentha kwa brazing ndi nthawi yogwira ziyenera kuyendetsedwa bwino.Kumeta ubweya wa carbon zitsulo olowa brazed ndi angapo monga malata lead solders akuwonetsedwa mu Table 1. Pakati pawo, mphamvu olowa brazed ndi 50% w (SN) ndi apamwamba, ndi olowa mphamvu welded ndi antimony free solder ndi apamwamba kuposa. kuti ndi antimoni.

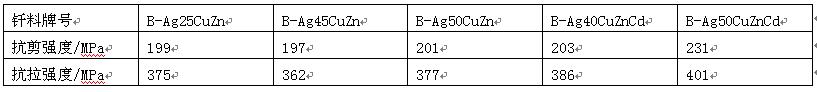

Table 1 mphamvu yakumeta ubweya wa zitsulo za kaboni zomangika ndi solder ya malata

Mukawotcha chitsulo cha kaboni ndi chitsulo chochepa cha alloy, mkuwa weniweni, zinki zamkuwa ndi zitsulo zamkuwa zamkuwa zimagwiritsidwa ntchito makamaka.Mkuwa woyengedwa uli ndi malo osungunuka kwambiri ndipo ndi osavuta oxidize chitsulo choyambira panthawi yachitsulo.Amagwiritsidwa ntchito kwambiri popangira gasi wotetezedwa ndi chitsulo cha vacuum brazing.Komabe, ziyenera kukumbukiridwa kuti kusiyana pakati pa ziwalo zomangika kuyenera kukhala kosachepera 0.05mm kuti tipewe vuto lomwe kusiyana kwa mgwirizano sikungatheke chifukwa cha madzi abwino amkuwa.Zitsulo za carbon ndi low alloy steel joints zomangidwa ndi mkuwa wangwiro zimakhala ndi mphamvu zambiri.Nthawi zambiri, mphamvu yakumeta ubweya ndi 150 ~ 215mpa, pomwe mphamvu yokhazikika imagawidwa pakati pa 170 ~ 340mpa.

Poyerekeza ndi mkuwa wangwiro, malo osungunuka a mkuwa wa zinc solder amachepa chifukwa cha kuwonjezera kwa Zn.Pofuna kupewa kuphulika kwa Zn panthawi ya brazing, kumbali imodzi, pang'ono ya Si ikhoza kuwonjezeredwa ku solder yamkuwa ya zinc;Kumbali inayi, njira zowotchera mwachangu ziyenera kugwiritsidwa ntchito, monga kuyatsa moto, kuwotcha kwa induction ndi dip brazing.Malumikizidwe achitsulo cha kaboni ndi chitsulo chotsika cha alloy chomangidwa ndi chitsulo chamkuwa cha zinc chimakhala ndi mphamvu zabwino komanso pulasitiki.Mwachitsanzo, kulimba kwamphamvu komanso kumeta ubweya wazitsulo za kaboni zolumikizidwa ndi solder ya b-cu62zn kufika 420MPa ndi 290mpa.Malo osungunuka a silver copper station solder ndi otsika kuposa a copper zinc solder, omwe ndi abwino kuwotcherera singano.Chitsulo chodzaza ichi ndi choyenera kuwotcha lamoto, kuyika moto ndikuwotcha ng'anjo ya chitsulo cha kaboni ndi chitsulo chochepa cha alloy, koma zomwe zili mu Zn ziyenera kuchepetsedwa momwe zingathere pakuwotcha kwa ng'anjo, ndikuwotcha kuyenera kuwonjezeka.Brazing carbon steel ndi low alloy steel with silver copper zinc filler zitsulo zimatha kupeza zolumikizana ndi mphamvu zabwino komanso pulasitiki.Deta yeniyeni yalembedwa mu Table 2.

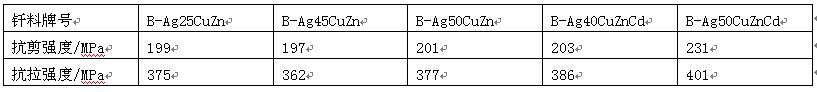

Table 2 mphamvu ya olowa mpweya zitsulo otsika brazed ndi siliva mkuwa zinc solder

(2) Flux: kutulutsa kapena kutchingira gasi kudzagwiritsidwa ntchito popangira chitsulo cha carbon ndi chitsulo chochepa cha alloy.Flux nthawi zambiri imatsimikiziridwa ndi zitsulo zosankhidwa zazitsulo ndi brazing.Pamene tini lead solder imagwiritsidwa ntchito, madzi osakanikirana a zinc chloride ndi ammonium chloride atha kugwiritsidwa ntchito ngati flux kapena flux ina yapadera.Zotsalira za fluxzi nthawi zambiri zimakhala zowononga kwambiri, ndipo cholumikizira chiyenera kutsukidwa bwino pambuyo powotcha.

Mukawotcha ndi zitsulo zamkuwa zodzaza zinki, fb301 kapena fb302 flux iyenera kusankhidwa, ndiko kuti, borax kapena kusakaniza kwa borax ndi boric acid;Powotcha moto, chisakanizo cha methyl borate ndi formic acid chingagwiritsidwenso ntchito ngati brazing flux, momwe mpweya wa B2O3 umagwira ntchito yochotsa filimu.

Mukamagwiritsa ntchito zitsulo zamkuwa zamkuwa zachitsulo, fb102, fb103 ndi fb104 brazing fluxes zitha kusankhidwa, ndiye kuti, kusakaniza kwa borax, boric acid ndi ma fluoride ena.Zotsalira za fluxzi zimawononga kumlingo wina ndipo ziyenera kuchotsedwa pambuyo pakuwotcha.

2. Zipangizo zamakono

Pamwamba kuti welded ayenera kutsukidwa ndi makina kapena mankhwala njira kuonetsetsa kuti okusayidi filimu ndi organic kanthu kuchotsedwa kwathunthu.Malo otsukidwawo asakhale aukali kwambiri ndipo asatsatire tchipisi tachitsulo kapena dothi lina.

Chitsulo cha carbon ndi chitsulo chochepa cha alloy chikhoza kupangidwa ndi njira zosiyanasiyana zowomba.Panthawi yoyaka moto, moto wosalowerera kapena wocheperako uyenera kugwiritsidwa ntchito.Panthawi yogwira ntchito, kutentha kwachindunji kwa zitsulo zodzaza ndi chitsulo ndi kutentha kwamoto kuyenera kupewedwa momwe mungathere.Njira zowotchera mwachangu monga induction brazing ndi dip brazing ndizoyenera kwambiri pakuwotcha kwachitsulo chozimitsidwa komanso chotenthedwa.Pa nthawi yomweyi, kuzimitsa kapena kuwotcha pa kutentha kochepa kusiyana ndi kutentha kuyenera kusankhidwa kuti zitsulo zoyambira zikhale zofewa.Pamene brazing otsika aloyi mkulu mphamvu zitsulo m'mlengalenga zoteteza, osati mkulu chiyero cha mpweya chofunika, komanso mpweya flux ayenera kugwiritsidwa ntchito kuonetsetsa kunyowetsa ndi kufalikira kwa filler zitsulo pamwamba zitsulo m'munsi.

Kutuluka kotsalirako kumatha kuchotsedwa ndi mankhwala kapena njira zamakina.Zotsalira za organic brazing flux zimatha kupukutidwa kapena kutsukidwa ndi mafuta, mowa, acetone ndi zosungunulira zina organic;Zotsalira za zinc chloride ndi ammonium chloride ziyenera kuchepetsedwa mumadzi amadzimadzi a NaOH poyamba, kenako kutsukidwa ndi madzi otentha ndi ozizira;Boric acid ndi boric acid flux zotsalira zimakhala zovuta kuchotsa, ndipo zimatha kuthetsedwa ndi njira zamakina kapena kumizidwa kwa nthawi yayitali m'madzi okwera.

Nthawi yotumiza: Jun-13-2022