1. Solder

Mitundu yonse ya solders ndi kutentha otsika kuposa 3000 ℃ angagwiritsidwe ntchito W brazing, ndi solders mkuwa kapena siliva zochokera angagwiritsidwe ntchito zigawo zikuluzikulu ndi kutentha m'munsi kuposa 400 ℃; Golide, manganese based, manganese based, palladium based or drill based filler zitsulo nthawi zambiri amagwiritsidwa ntchito pazinthu zomwe zimagwiritsidwa ntchito pakati pa 400 ℃ ndi 900 ℃; Pazigawo zomwe zimagwiritsidwa ntchito pamwamba pa 1000 ℃, zitsulo zoyera monga Nb, Ta, Ni, Pt, PD ndi Mo zimagwiritsidwa ntchito kwambiri. Kutentha kogwira ntchito kwa zigawo zokongoletsedwa ndi solder ya platinamu kwafika 2150 ℃. Ngati 1080 ℃ diffusion mankhwala ikuchitika pambuyo brazing, pazipita ntchito kutentha akhoza kufika 3038 ℃.

Ambiri mwa ogulitsa omwe amagwiritsidwa ntchito popangira brazing w angagwiritsidwe ntchito powotcha Mo, ndipo zogulitsa zamkuwa kapena siliva zingagwiritsidwe ntchito pazinthu za Mo zomwe zimagwira ntchito pansi pa 400 ℃; Pazida zamagetsi ndi zida zosagwirizana ndi 400 ~ 650 ℃, Cu Ag, Au Ni, PD Ni kapena Cu Ni ogulitsa angagwiritsidwe ntchito; Titaniyamu yozikidwa pazitsulo kapena zitsulo zoyera zazitsulo zokhala ndi malo osungunuka kwambiri zitha kugwiritsidwa ntchito pazinthu zomwe zimagwira ntchito kutentha kwambiri. Zindikirani kuti zitsulo zochokera ku manganese, cobalt ndi nickel based filler zitsulo nthawi zambiri sizoyenera kupewa kupanga ma brittle intermetallic compounds m'malo olumikizirana mafupa.

Pamene zigawo za TA kapena Nb zimagwiritsidwa ntchito pansi pa 1000 ℃, mkuwa wochokera, manganese opangidwa ndi cobalt, titaniyamu yochokera, nickel based, golidi ndi jekeseni wa palladium akhoza kusankhidwa, kuphatikizapo Cu Au, Au Ni, PD Ni ndi Pt Au_ Ni ndi Cu Sn ogulitsa ali ndi wettability wabwino wa TA ndi Nb, kupanga bwino kwa mgwirizano wolumikizana ndi kupanga msoko. Monga zitsulo zokhala ndi siliva zodzaza ndi siliva zimakonda kupangitsa kuti zitsulo za brazing zikhale zolimba, ziyenera kupewedwa momwe zingathere. Pazigawo zomwe zimagwiritsidwa ntchito pakati pa 1000 ℃ ndi 1300 ℃, zitsulo zoyera Ti, V, Zr kapena ma alloys otengera zitsulo izi zomwe zimapanga zolimba zopanda malire komanso zamadzimadzi zomwe zili nazo zimasankhidwa ngati zitsulo zodzaza ndi brazing. Kutentha kwautumiki kukakwera, zitsulo zodzaza ndi HF zitha kusankhidwa.

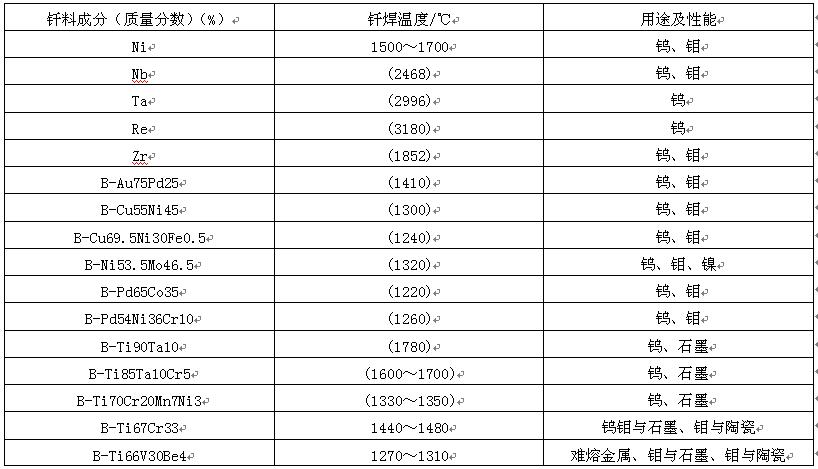

W. Onani tebulo 13 la zitsulo zodzaza zitsulo za Mo, Ta ndi Nb pa kutentha kwakukulu.

Table 13 brazing filler zitsulo zopangira kutentha kwambiri kwazitsulo zosakanizika

Pamaso brazing, m'pofunika mosamala kuchotsa okusayidi pamwamba pa zitsulo refractory. Kupera kwamakina, kuphulika kwa mchenga, kuyeretsa ndi akupanga kapena kuyeretsa mankhwala kungagwiritsidwe ntchito. Brazing idzachitika mwamsanga pambuyo kuyeretsa ndondomeko.

Chifukwa cha kuwonongeka kwachilengedwe kwa W, zigawo za w ziyenera kusamaliridwa mosamala mu gawo la msonkhano wachigawo kuti zisawonongeke. Pofuna kupewa mapangidwe a brittle tungsten carbide, kulumikizana kwachindunji pakati pa W ndi graphite kuyenera kupewedwa. Kupanikizika chifukwa cha kuwotcherera kusanachitike kapena kuwotcherera kumathetsedwa musanawotchere. W ndi osavuta kwambiri oxidize kutentha kukakwera. Digiri ya vacuum iyenera kukhala yokwanira pakuwotcha. Pamene brazing ikuchitika mkati mwa kutentha kwa 1000 ~ 1400 ℃, digiri ya vacuum idzakhala yosachepera 8 × 10-3Pa. Pofuna kukonza kutentha kwa remelting ndi kutentha kwautumiki wa mgwirizano, ndondomeko yowonongeka ikhoza kuphatikizidwa ndi chithandizo cha kufalikira pambuyo pa kuwotcherera. Mwachitsanzo, solder ya b-ni68cr20si10fel imagwiritsidwa ntchito kupaka W pa 1180 ℃. Pambuyo mankhwala atatu diffusion 1070 ℃ / 4h, 1200 ℃ / 3.5h ndi 1300 ℃ / 2h pambuyo kuwotcherera, kutentha utumiki wa olowa brazed akhoza kufika oposa 2200 ℃.

Chigawo chaching'ono cha kukula kwamafuta chiyenera kuganiziridwa posonkhanitsa cholumikizira cha Mo, ndipo kusiyana kwapakati kuyenera kukhala mkati mwa 0.05 ~ 0.13MM. Ngati choyikacho chikugwiritsidwa ntchito, sankhani chinthu chokhala ndi kagawo kakang'ono ka kukulitsa kutentha. Mo recrystallization imachitika pamene kuwomba kwa lawi, ng'anjo yoyendetsedwa ndi mpweya, ng'anjo yovundikira, ng'anjo yotenthetsera ndi kutenthetsa kukana kupitilira kutentha kwa recrystallization kapena kutentha kwa recrystallization kumachepa chifukwa cha kufalikira kwa zinthu zogulitsa. Choncho, pamene kutentha kwamoto kuli pafupi ndi kutentha kwa recrystallization, kufupikitsa nthawi yowotcha, kumakhala bwino. Mukawotcha pamwamba pa kutentha kwa recrystallization ya Mo, nthawi yowotchera ndi kuzizira ziyenera kuwongoleredwa kuti zipewe kusweka komwe kumachitika chifukwa chakuzizira kwambiri. Pamene flame brazing ya oxyacetylene imagwiritsidwa ntchito, ndi bwino kugwiritsa ntchito madzi osakanikirana, ndiko kuti, borate ya mafakitale kapena silver brazing flux kuphatikizapo kutentha kwapamwamba komwe kumakhala ndi calcium fluoride, yomwe ingapeze chitetezo chabwino. Njirayo ndikuyamba kuvala siliva wowotcha siliva pamwamba pa Mo, ndiyeno kuvala kutentha kwambiri. Silver brazing flux imakhala ndi ntchito yotsika kutentha, ndipo kutentha kotentha kwambiri kumatha kufika 1427 ℃.

Zigawo za TA kapena Nb zimayikidwa bwino pansi pa vacuum, ndipo digiri ya vacuum ndi yosachepera 1.33 × 10-2Pa. Ngati brazing ikuchitika pansi pa chitetezo cha mpweya woipa, zonyansa za mpweya monga carbon monoxide, ammonia, nayitrogeni ndi carbon dioxide ziyenera kuchotsedwa. Pamene brazing kapena kukana brazing ikuchitika mumlengalenga, chitsulo chapadera cha brazing filler ndi flux yoyenera iyenera kugwiritsidwa ntchito. Pofuna kupewa TA kapena Nb kuti isakhudze mpweya kutentha kwambiri, chitsulo chosanjikiza chamkuwa kapena faifi tambala chimatha kukutidwa pamwamba ndipo chithandizo chofananira cha annealing chitha kuchitidwa.

Nthawi yotumiza: Jun-13-2022