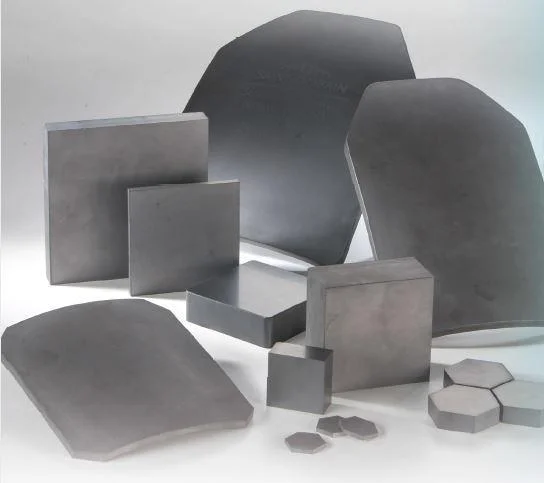

Zoumba za silicon carbide zimakhala ndi kutentha kwakukulu, kukana kutentha kwa okosijeni, kukana kuvala bwino, kukhazikika kwamafuta, kukhazikika kwamafuta pang'ono, kukhathamiritsa kwamafuta, kuuma kwakukulu, kukana kutentha, kukana kwa dzimbiri ndi zinthu zina zabwino kwambiri.Zakhala zikugwiritsidwa ntchito kwambiri pamagalimoto, kumakina, kuteteza chilengedwe, ukadaulo wazamlengalenga, zamagetsi, mphamvu ndi zina, ndipo zakhala ngati choumba chosasinthika chosasinthika chomwe chimagwira ntchito bwino m'mafakitale ambiri.Tsopano ndiroleni ndikuwonetseni!

Kuyimba mopanda kukakamiza

Kuyimba mopanda Pressure kumawonedwa ngati njira yodalirika kwambiri ya SiC sintering.Malinga ndi njira zosiyanasiyana zopangira sintering, sintering yopanda mphamvu imatha kugawidwa kukhala solid-phase sintering ndi liquid-phase sintering.Kupyolera mu ultra-fine β- A mlingo woyenera wa B ndi C (oxygen wocheperapo 2%) anawonjezeredwa ku SiC powder panthawi imodzimodzi, ndi s.proehazka idasiyidwa ku SiC sintered thupi ndi kachulukidwe kuposa 98% pa 2020 ℃.A. Mulla et al.Al2O3 ndi Y2O3 ankagwiritsidwa ntchito monga zowonjezera ndi sintered pa 1850-1950 ℃ kwa 0.5 μ m β- SiC (tinthu pamwamba ili ndi pang'ono SiO2).Kachulukidwe wachibale wa zoumba za SiC zopezedwa ndizokulirapo kuposa 95% ya kachulukidwe kamalingaliro, ndipo kukula kwambewu ndi kochepa komanso kukula kwapakati.Ndi 1.5 microns.

Hot atolankhani sintering

SiC yoyera imatha kutenthedwa pang'onopang'ono pa kutentha kwambiri popanda zowonjezera zowonjezera, anthu ambiri amagwiritsa ntchito njira yotentha yotentha ya SiC.Pakhala pali malipoti ambiri okhudza kukanikiza kotentha kwa SiC powonjezera zothandizira.Alliegro ndi al.Anaphunzira zotsatira za boron, aluminium, faifi tambala, chitsulo, chromium ndi zina zowonjezera zitsulo pa SiC densification.Zotsatira zikuwonetsa kuti aluminiyumu ndi chitsulo ndizowonjezera zowonjezera zolimbikitsa SiC hot pressing sintering.FFlange adaphunzira zotsatira za kuwonjezera kuchuluka kosiyana kwa Al2O3 pazinthu za SiC yotentha kwambiri.Zimaganiziridwa kuti kachulukidwe ka SiC yotenthedwa yotentha ikugwirizana ndi njira ya kusungunuka ndi mvula.Komabe, makina osindikizira otentha amatha kungotulutsa magawo a SiC okhala ndi mawonekedwe osavuta.Kuchuluka kwa zinthu zopangidwa ndi nthawi imodzi yotentha makina osindikizira sintering ndizochepa kwambiri, zomwe sizikugwirizana ndi kupanga mafakitale.

Hot isostatic kukanikiza sintering

Pofuna kuthana ndi zofooka za ndondomeko ya sintering yachikhalidwe, mtundu wa B ndi mtundu wa C unagwiritsidwa ntchito ngati zowonjezera ndipo teknoloji yotentha ya isostatic yosindikizira sintering inakhazikitsidwa.Pa 1900 ° C, zoumba zabwino za crystalline zokhala ndi kachulukidwe kakang'ono kuposa 98 zidapezeka, ndipo mphamvu yopindika kutentha imatha kufika 600 MPa.Ngakhale kutentha kwa isostatic kukanikiza sintering kumatha kutulutsa zinthu zowoneka bwino zokhala ndi mawonekedwe ovuta komanso makina abwino amakina, sintering iyenera kusindikizidwa, zomwe zimakhala zovuta kukwaniritsa kupanga mafakitale.

Reaction sintering

Reaction sintered silicon carbide, yomwe imadziwikanso kuti self bonded silicon carbide, imatanthawuza momwe ma porous billet amachitira ndi mpweya kapena gawo lamadzimadzi kuti apititse patsogolo khalidwe la billet, kuchepetsa porosity, ndi sinter zomalizidwa ndi mphamvu zinazake ndi kulondola kwenikweni.tengani ufa wa α-SiC ndi graphite zimasakanizidwa mugawo lina ndikutenthetsa mpaka pafupifupi 1650 ℃ kuti apange billet lalikulu.Panthawi imodzimodziyo, imalowa kapena imalowa mu billet kudzera mu mpweya wa Si ndikuchita ndi graphite kupanga β-SiC, kuphatikizapo α-SiC particles zomwe zilipo.Si ikalowetsedwa kwathunthu, momwe thupi la sintered lilili ndi kachulukidwe wathunthu komanso kukula kosacheperako kumatha kupezeka.Poyerekeza ndi njira zina za sintering, kukula kwa kusintha kwa sintering mu ndondomeko ya densification ndi yaying'ono, ndipo mankhwala omwe ali ndi kukula kolondola akhoza kukonzekera.Komabe, kukhalapo kwa kuchuluka kwa SiC m'thupi loyipitsidwa kumapangitsa kuti kutentha kwamphamvu kwa sintered SiC ceramics kuipire.

Nthawi yotumiza: Jun-08-2022