Ng'anjo ya Vacuum Debinding and Sintering (MIM Furnace, ng'anjo ya Powder metallurgy)

Makhalidwe

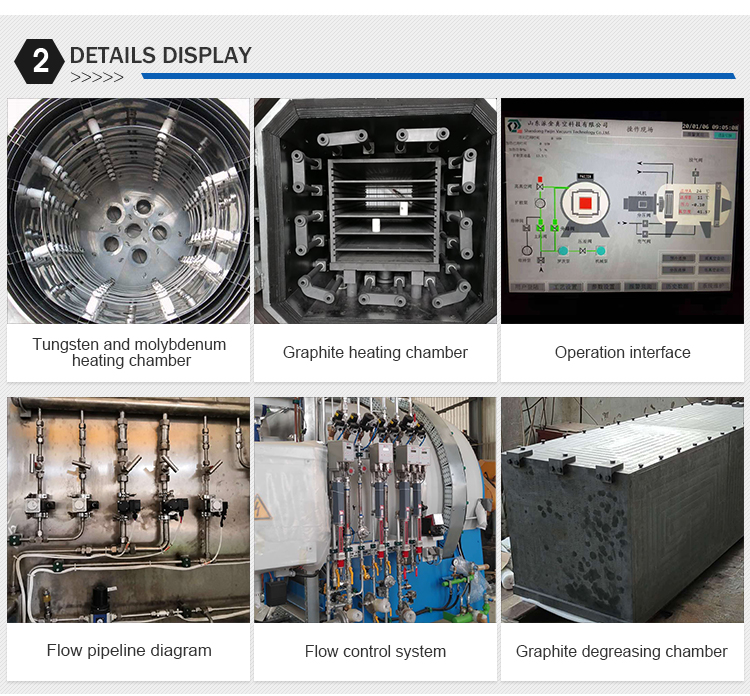

1. graphite insulation screen / zitsulo chophimba kusankha kusankha, Kutentha element 360 digiri mozungulira radiation kutentha, odalirika kutchinjiriza kapangidwe.

2. Kutentha kwakukulu kofanana ndi kutentha kwabwino

3. Vacuum partial pressure / multi-area control control function.

4. Zida zodziwikiratu, chitetezo chokwanira komanso ma alarm achilendo.

5. Kuwongolera njira zolondola kuti mukwaniritse gawo lokhazikika komanso kupewa kuipitsidwa kwa magawo ndi malo otentha.

6. Ndi bokosi losindikizidwa la degreasing ndi vacuum condenser kuti muchepetse kuipitsidwa kwa chipinda chotenthetsera ndi unit.

7.Kuletsa kuipitsa kwa zigawo za ng'anjo. Bokosi la degreasing lalikulu limagwiritsidwa ntchito kuthana ndi kuchuluka kwa zowonjezera zowonjezera.

8. Lili ndi ntchito za kusinthasintha kwa vacuum, vacuum sintering, micro-positive pressure sintering ndi zina zotero.

9. Mapangidwe aposachedwa kwambiri opangira matenthedwe ndi zida zimagwiritsidwa ntchito, kukana kukakamiza kumakhala kolimba, ndipo kupulumutsa mphamvu kumawonekera.

10.Ili ndi ntchito za kutentha kwambiri ndi alamu yowonjezereka, chitetezo cha makina odziwikiratu, chodziwikiratuoverpressure mpumulo chitetezo, zochita interlock ndi zina zotero, mkulu zida chitetezo.

11.Kugwira ntchito kwakutali, kuzindikira zolakwika zakutali ndi ntchito zokweza mapulogalamu akutali, etc.

Standard model specifications ndi magawo

| Chitsanzo | PJSJ-gr-30-1600 | PJSJ-gr-60-1600 | PJSJ-gr-100-1600 | PJSJ-gr-200-1600 | PJSJ-gr-450-1600 |

| Malo otentha otentha LWH (mm) | 200*200*300 | 300*300* 600 | 300*300* 900 | 400*400* 1200 | 500*500* 1800 |

| Kulemera kwa katundu (kg) | 100 | 200 | 400 | 600 | 10000 |

| Mphamvu yotentha (kw) | 65 | 80 | 150 | 200 | 450 |

| Kutentha kwakukulu (℃) | 1600 | ||||

| Kuwongolera kutentha (℃) | ±1 | ||||

| Kutentha kwa ng'anjo (℃) | ±3 | ||||

| Digiri ya vacuum ya ntchito (Pa) | 4.0 * E -1 | ||||

| Kupopera mitengo (mpaka 5 pa) | ≤10 min | ||||

| Kukwera kwa Pressure (Pa/H) | ≤ 0.5 | ||||

| Debinding rate | >97.5% | ||||

| Njira yothetsera | N2 mu kupsinjika maganizo, H2 mumlengalenga | ||||

| Gasi wolowetsa | N2, H2, Ayi | ||||

| Njira yozizira | kuziziritsa kwa gasi wa inert | ||||

| Sintering njira | Vacuum sintering, pang'onopang'ono kuthamanga sintering, osapanikizika sintering | ||||

| Kapangidwe ka ng'anjo | Chopingasa, chipinda chimodzi | ||||

| Njira yotsegulira chitseko cha ng'anjo | Mtundu wa hinge | ||||

| Kutentha zinthu | graphit Kutentha zinthu | ||||

| Chipinda chotenthetsera | Kapangidwe ka Graphit molimba mtima komanso mofewa | ||||

| Thermocouple | C Mtundu | ||||

| PLC & zinthu zamagetsi | Siemens | ||||

| Wowongolera kutentha | EUROTHERM | ||||

| Pampu ya vacuum | Pampu yamakina ndi pampu ya mizu | ||||

| Masanjidwe osankhidwa mwamakonda | |||||

| Kutentha kwakukulu | 1300-2800 ℃ | ||||

| Kutentha kwakukulu kwa digiri | 6.7 * E -3 Pa | ||||

| Kapangidwe ka ng'anjo | Chopingasa, Choyimirira, Chipinda chimodzi | ||||

| Njira yotsegulira zitseko | Mtundu wa hinge, Mtundu wokweza, Mtundu wa Flat | ||||

| Kutentha zinthu | Zinthu zotenthetsera za graphit, zinthu zotenthetsera za Mo | ||||

| Chipinda chotenthetsera | Wopangidwa ndi graphit anamva, Zonse zowonetsera zitsulo | ||||

| Mapampu a vacuum | Pampu yamakina ndi pampu ya mizu; Makina, Mizu ndi mapampu ofalitsa | ||||

| PLC & zinthu zamagetsi | Siemens; Omuroni; Mitsubishi; Siemens | ||||

| Wowongolera kutentha | EUROTHERM;S HIMADEN | ||||