1. Kulimba mtima

Ndizovuta kuyika zida za ceramic ndi ceramic, ceramic ndi zitsulo. Zambiri mwa solder zimapanga mpira pamtunda wa ceramic, wosanyowetsa pang'ono kapena osanyowa. Chitsulo chodzaza ndi brazing chomwe chimatha kunyowetsa ma ceramics ndichosavuta kupanga mitundu yosiyanasiyana ya brittle (monga carbides, silicides ndi ternary kapena multivariate compounds) pamawonekedwe olumikizirana panthawi ya brazing. Kukhalapo kwa mankhwalawa kumakhudza makina a olowa. Kuonjezera apo, chifukwa cha kusiyana kwakukulu kwa ma coefficients owonjezera kutentha pakati pa ceramic, zitsulo ndi solder, padzakhala kupanikizika kotsalira mu mgwirizano pambuyo pozizira kutentha kwa kutentha kwa kutentha, zomwe zingayambitse kusweka kwa mgwirizano.

The wettability wa solder pa ceramic pamwamba akhoza kusintha mwa kuwonjezera yogwira zitsulo zinthu solder wamba; Kutentha kwapansi ndi nthawi yochepa yowotcha imatha kuchepetsa zotsatira za mawonekedwe; Kupsyinjika kwamafuta ophatikizana kumatha kuchepetsedwa popanga mawonekedwe olumikizana oyenera ndikugwiritsa ntchito chitsulo chimodzi kapena zingapo zosanjikiza ngati gawo lapakati.

2. Solder

Ceramic ndi zitsulo nthawi zambiri zimalumikizidwa mu ng'anjo ya vacuum kapena haidrojeni ndi ng'anjo ya argon. Kuphatikiza pa mawonekedwe wamba, zitsulo za brazing filler pazida zamagetsi za vacuum ziyeneranso kukhala ndi zofunika zina zapadera. Mwachitsanzo, solder sayenera kukhala ndi zinthu zomwe zimapanga kuthamanga kwa nthunzi, kuti zisapangitse kutayikira kwa dielectric ndi poizoni wa cathode wa zida. Kawirikawiri zimatchulidwa kuti pamene chipangizocho chikugwira ntchito, mphamvu ya nthunzi ya solder siyenera kupitirira 10-3pa, ndipo zonyansa zamtundu wa nthunzi zomwe zimakhalapo sizidzapitirira 0.002% ~ 0.005%; The w (o) wa solder sayenera upambana 0.001%, pofuna kupewa nthunzi kwaiye pa brazing mu haidrojeni, amene angayambitse splash wa chitsulo solder; Kuphatikiza apo, solder iyenera kukhala yoyera komanso yopanda ma oxides padziko lapansi.

Mukawotcha pambuyo pazitsulo za ceramic, mkuwa, maziko, mkuwa wasiliva, mkuwa wagolide ndi zitsulo zina za alloy brazing filler zingagwiritsidwe ntchito.

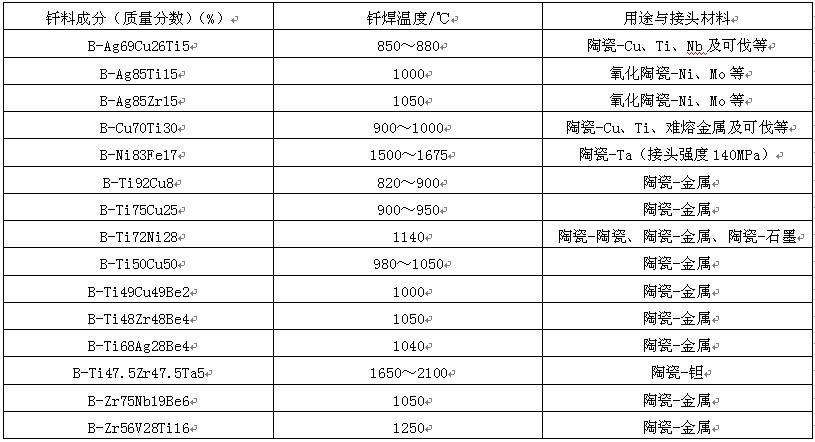

Pakuwotcha mwachindunji kwa ceramics ndi zitsulo, zitsulo zodzaza ndi brazing zomwe zili ndi zinthu zogwira ntchito za Ti ndi Zr zidzasankhidwa. Zitsulo za binary filler makamaka ndi Ti Cu ndi Ti Ni, zomwe zitha kugwiritsidwa ntchito pa 1100 ℃. Pakati pa ternary solder, Ag Cu Ti (W) (TI) ndiye solder yomwe imagwiritsidwa ntchito kwambiri, yomwe imatha kugwiritsidwa ntchito powotcha mwachindunji ma ceramics ndi zitsulo zosiyanasiyana. Chitsulo cha ternary filler chitha kugwiritsidwa ntchito ndi zojambulazo, ufa kapena Ag Cu eutectic filler zitsulo ndi Ti powder. B-ti49be2 brazing filler chitsulo imakhala ndi kukana kwa dzimbiri kofanana ndi chitsulo chosapanga dzimbiri komanso kutsika kwa nthunzi. Ikhoza kusankhidwa mwapadera muzitsulo zosindikizira za vacuum ndi makutidwe ndi okosijeni komanso kutsekemera kwamadzimadzi. Mu ti-v-cr solder, kutentha kosungunuka ndikotsika kwambiri (1620 ℃) pamene w (V) ndi 30%, ndipo kuwonjezera kwa Cr kumatha kuchepetsa kutentha kwa kutentha. B-ti47.5ta5 solder popanda Cr yagwiritsidwa ntchito popangira alumina ndi magnesium oxide, ndipo cholumikizira chake chimatha kugwira ntchito pakutentha kozungulira kwa 1000 ℃. Table 14 ikuwonetsa kusinthasintha kwachangu kolumikizana mwachindunji pakati pa ceramic ndi chitsulo.

Table 14 yogwira zitsulo zodzaza ndi zitsulo za ceramic ndi zitsulo

2. Zipangizo zamakono

Makatani opangidwa ndi zitsulo zoyambira amatha kuyatsidwa mu gasi woyeretsa kwambiri, hydrogen kapena vacuum. Vacuum brazing nthawi zambiri amagwiritsidwa ntchito powotcha zitsulo za ceramic popanda zitsulo.

(1) Universal brazing ndondomeko ya chilengedwe chonse brazing ndondomeko ya ceramic ndi zitsulo akhoza kugawidwa m'njira zisanu ndi ziwiri: kuyeretsa pamwamba, kupaka phala, ceramic pamwamba metallization, nickel plating, brazing ndi post weld kuyendera.

Cholinga cha kuyeretsa pamwamba ndikuchotsa banga lamafuta, banga la thukuta ndi filimu ya oxide pamwamba pazitsulo zoyambira. Zitsulo ndi solder adzakhala degreased poyamba, ndiye okusayidi filimu adzachotsedwa ndi asidi kapena alkali kutsuka, osambitsidwa ndi madzi oyenda ndi zouma. Magawo omwe ali ndi zofunika kwambiri amatenthedwa mu ng'anjo yowunikidwa kapena ng'anjo ya haidrojeni (njira ya bombardment ya ion itha kugwiritsidwanso ntchito) pa kutentha koyenera komanso nthawi yoyeretsa pamwamba pazigawo. Ziwalo zotsukidwa sizimakhudzana ndi zinthu zamafuta kapena manja opanda kanthu. Adzayikidwa nthawi yomweyo munjira yotsatira kapena mu chowumitsira. Iwo sadzawululidwa ndi mpweya kwa nthawi yaitali. Ziwalo za ceramic ziyenera kutsukidwa ndi acetone ndi akupanga, kutsukidwa ndi madzi oyenda, kenako kuwiritsa kawiri ndi madzi opangidwa ndi deionized kwa 15min nthawi iliyonse.

Phala ❖ kuyanika ndi njira yofunika kwambiri ya ceramic metallization. Pa ❖ kuyanika, ntchito pa ceramic pamwamba kuti zitsulo ndi burashi kapena phala ❖ kuyanika makina. Makulidwe opaka nthawi zambiri amakhala 30 ~ 60mm. Phala nthawi zambiri limakonzedwa kuchokera ku ufa wachitsulo (nthawi zina zitsulo zokwana oxide zimawonjezeredwa) ndi kukula kwa tinthu pafupifupi 1 ~ 5um ndi zomatira organic.

Magawo a ceramic omwe amayikidwa amatumizidwa ku ng'anjo ya haidrojeni ndikuthiridwa ndi hydrogen yonyowa kapena ammonia wosweka pa 1300 ~ 1500 ℃ kwa 30 ~ 60min. Pazigawo za ceramic zokutidwa ndi ma hydrides, ziyenera kutenthedwa mpaka 900 ℃ kuti ziwononge ma hydrides ndikuchitapo kanthu ndi zitsulo zoyera kapena titaniyamu (kapena zirconium) zotsalira pa ceramic pamwamba kuti zipeze zokutira zachitsulo pamtunda.

Kwa wosanjikiza wazitsulo wa Mo Mn, kuti unyowe ndi solder, nickel wosanjikiza wa 1.4 ~ 5um uyenera kupangidwa ndi electrop kapena wokutidwa ndi ufa wa nickel. Ngati kutentha kwa brazing kuli kochepera 1000 ℃, wosanjikiza wa nickel uyenera kutenthedwa mu ng'anjo ya haidrojeni. Kutentha kwa sintering ndi nthawi ndi 1000 ℃ / 15 ~ 20min.

Zida za ceramic zomwe zimagwiritsidwa ntchito ndi zigawo zachitsulo, zomwe zidzasonkhanitsidwa pamodzi ndi chitsulo chosapanga dzimbiri kapena graphite ndi nkhungu za ceramic. Solder idzayikidwa pamalumikizidwe, ndipo chogwirira ntchitocho chizikhala choyera nthawi yonseyi, ndipo sichidzakhudzidwa ndi manja opanda kanthu.

Kuwotcha kuyenera kuchitika mu ng'anjo ya argon, haidrojeni kapena vacuum. Kutentha kwa brazing kumadalira chitsulo chodzaza ndi brazing. Pofuna kupewa kusweka kwa magawo a ceramic, kuzizira sikuyenera kukhala kofulumira. Kuphatikiza apo, kuwotcha kumathanso kugwiritsa ntchito kukakamiza kwina (pafupifupi 0.49 ~ 0.98mpa).

Kuphatikiza pa kuyang'anitsitsa kwapamwamba, ma welds a brazed adzakhalanso ndi mantha a kutentha ndi kuyang'anitsitsa katundu wamakina. Zigawo zosindikizira za zida za vacuum ziyeneranso kuyesedwa kutayikira malinga ndi malamulo oyenera.

(2) Kuwotcha molunjika pamene mukuwotcha mwachindunji (njira yachitsulo yogwira ntchito), choyamba yeretsani pamwamba pazitsulo za ceramic ndi zitsulo, ndiyeno sonkhanitsani. Pofuna kupewa ming'alu yomwe imayambitsidwa ndi ma coefficients osiyanasiyana owonjezera amafuta azinthu zamagulu, gawo lotchinga (gawo limodzi kapena zingapo za mapepala achitsulo) limatha kuzunguliridwa pakati pa ma welds. Chitsulo chodzaza ndi brazing chimangiriridwa pakati pa ma welds awiri kapena kuyikidwa pamalo pomwe kusiyana kumadzadzidwa ndi zitsulo zodzaza ndi brazing momwe kungathekere, ndiyeno kuwomba kumachitidwa ngati chitsulo chavacuum wamba.

Ngati solder ya Ag Cu Ti ikugwiritsidwa ntchito powotcha mwachindunji, njira ya vacuum brazing iyenera kutengedwa. Pamene vakuyumu digiri mu ng'anjo kufika 2.7 × Yambani Kutentha pa 10-3pa, ndi kutentha akhoza kuwuka mofulumira pa nthawi ino; Pamene kutentha kuli pafupi ndi malo osungunuka a solder, kutentha kumayenera kukwezedwa pang'onopang'ono kuti kutentha kwa mbali zonse za weldment zikhale zofanana; Pamene solder yasungunuka, kutentha kumayenera kukwezedwa mofulumira ku kutentha kwa kutentha, ndipo nthawi yogwira idzakhala 3 ~ 5min; Panthawi yozizirira, imaziziritsidwa pang'onopang'ono isanakwane 700 ℃, ndipo imatha kuzizidwa mwachilengedwe ndi ng'anjo pambuyo pa 700 ℃.

Pamene Ti Cu yogwira solder ikuwongoleredwa mwachindunji, mawonekedwe a solder akhoza kukhala Cu zojambulazo kuphatikiza Ti ufa kapena Cu mbali kuphatikiza Ti zojambulazo, kapena ceramic pamwamba akhoza yokutidwa ndi Ti powder plus Cu zojambulazo. Asanayambe kuwotcha, zitsulo zonse ziyenera kuchotsedwa ndi vacuum. The degassing kutentha kwa mpweya wopanda mkuwa adzakhala 750 ~ 800 ℃, ndi Ti, Nb, Ta, etc. adzakhala degassed pa 900 ℃ kwa 15min. Panthawi imeneyi, vacuum digiri sadzakhala zosakwana 6.7 × 10-3Pa. Pa brazing, kusonkhanitsa zigawo zikuluzikulu kuti welded mu fixture, kutentha iwo mu ng'anjo zingalowe kuti 900 ~ 1120 ℃, ndi akugwira nthawi 2 ~ 5min. Panthawi yonse yowotcha, digiri ya vacuum idzakhala yosachepera 6.7 × 10-3Pa.

Njira yowotcha ya Ti Ni ndiyofanana ndi njira ya Ti Cu, ndipo kutentha kwa brazing ndi 900 ± 10 ℃.

(3) Oxide brazing njira oxide brazing njira ndi njira yozindikiritsira kulumikizana kodalirika pogwiritsa ntchito gawo lagalasi lomwe limapangidwa ndi kusungunuka kwa oxide solder kuti ilowe muzoumba ndikunyowetsa zitsulo pamwamba. Ikhoza kugwirizanitsa zoumba ndi zoumba ndi zitsulo ndi zitsulo. Oxide brazing filler zitsulo zimapangidwa makamaka ndi Al2O3, Cao, Bao ndi MgO. Powonjezera B2O3, Y2O3 ndi ta2o3, zitsulo zodzaza ndi brazing zokhala ndi malo osungunuka osiyanasiyana komanso ma coefficients okulitsa amtundu amatha kupezeka. Kuphatikiza apo, zitsulo za fluoride brazing filler zomwe zili ndi CaF2 ndi NaF monga zigawo zikuluzikulu zitha kugwiritsidwanso ntchito kulumikiza zoumba ndi zitsulo kuti mupeze zolumikizira zolimba kwambiri komanso kukana kutentha kwambiri.

Nthawi yotumiza: Jun-13-2022