Kuwotcha kwachitsulo chosapanga dzimbiri

1. Kulimba mtima

Vuto lalikulu pakuwotcha kwachitsulo chosapanga dzimbiri ndikuti filimu ya oxide pamtunda imakhudza kwambiri kunyowetsa ndi kufalikira kwa solder.Zitsulo zosiyanasiyana zosapanga dzimbiri zimakhala ndi kuchuluka kwa Cr, ndipo zina zilinso ndi Ni, Ti, Mn, Mo, Nb ndi zinthu zina, zomwe zimatha kupanga ma oxides osiyanasiyana kapena ma oxide ophatikizika pamwamba.Pakati pawo, ma oxides Cr2O3 ndi TiO2 a Cr ndi Ti ndi okhazikika komanso ovuta kuchotsa.Mukawotcha mumlengalenga, kusinthasintha kogwira kuyenera kugwiritsidwa ntchito kuwachotsa;Mukawotcha mumlengalenga woteteza, filimu ya oxide imatha kuchepetsedwa pokhapokha mumlengalenga wachiyero wokhala ndi mame otsika komanso kutentha kokwanira;Mu vacuum brazing, ndikofunikira kukhala ndi vacuum yokwanira komanso kutentha kokwanira kuti mukwaniritse bwino.

Vuto lina lachitsulo chosapanga dzimbiri ndilokuti kutentha kwa kutentha kumakhudza kwambiri mapangidwe a zitsulo zoyambira.Kutentha kotentha kwachitsulo chosapanga dzimbiri cha austenitic sikuyenera kupitirira 1150 ℃, apo ayi mbewu zimakula kwambiri;Ngati chitsulo chosapanga dzimbiri cha austenitic chilibe chinthu chokhazikika cha Ti kapena Nb ndipo chili ndi mpweya wambiri, kutentha mkati mwa kutentha (500 ~ 850 ℃) kuyeneranso kupewedwa.Kuteteza kukana kwa dzimbiri kuti kuchepe chifukwa cha mvula ya chromium carbide.Kusankhidwa kwa kutentha kwa brazing kwa zitsulo zosapanga dzimbiri za martensitic ndizovuta kwambiri.Chimodzi ndicho kufananitsa kutentha kwamoto ndi kutentha kozimitsa, kuti muphatikize njira yowotchera ndi kutentha kwa kutentha;Chinanso ndi chakuti kutentha kwachitsulo kuyenera kukhala kochepa kusiyana ndi kutentha kwa kutentha kuti zitsulo zoyambira zisafewe panthawi yowotcha.Mfundo yosankha kutentha kwa brazing ya mpweya woumitsa chitsulo chosapanga dzimbiri ndi yofanana ndi ya chitsulo chosapanga dzimbiri cha martensitic, ndiko kuti, kutentha kwamoto kuyenera kufanana ndi njira yochizira kutentha kuti mupeze makina abwino kwambiri.

Kuphatikiza pazovuta zazikulu ziwiri zomwe zili pamwambazi, pali chizolowezi chosweka mtima pakuwotcha chitsulo chosapanga dzimbiri cha austenitic, makamaka mukamanga ndi chitsulo chamkuwa cha zinc.Pofuna kupewa kusweka kwa kupsinjika, chogwiritsira ntchito chiyenera kuchepetsedwa kupsinjika musanawombedwe, ndipo chogwirira ntchitocho chiyenera kutenthedwa mofanana panthawi ya brazing.

2. Kuwotcha zinthu

(1) Malinga ndi zofunikira pakugwiritsa ntchito zitsulo zosapanga dzimbiri, zitsulo zomwe zimagwiritsidwa ntchito kwambiri popangira zitsulo zosapanga dzimbiri zikuphatikizapo Tin Lead brazing filler zitsulo, zitsulo zasiliva zochokera ku brazing filler metal, copper based brazing filler metal, manganese based brazing filler zitsulo, faifi tambala brazing filler zitsulo ndi chitsulo chamtengo wapatali cha brazing filler chitsulo.

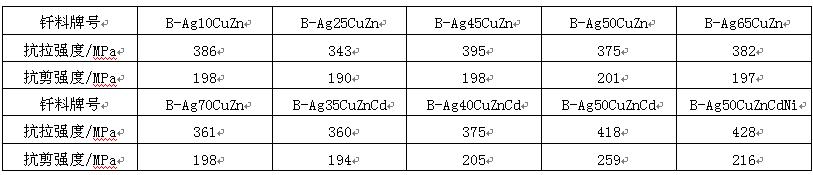

Tin lead solder imagwiritsidwa ntchito kwambiri pakuwotchera zitsulo zosapanga dzimbiri, ndipo ndiyoyenera kukhala ndi malata ambiri.Kukwera kwa malata mu solder kumapangitsanso kunyowa kwake pazitsulo zosapanga dzimbiri.Mphamvu zometa ubweya wa 1Cr18Ni9Ti zitsulo zosapanga dzimbiri zosapanga dzimbiri zomangika ndi zida zingapo zodziwika bwino za tini zimalembedwa mu Table 3. Chifukwa cha mphamvu zochepa zamagulu, amangogwiritsidwa ntchito popanga zingwe zokhala ndi mphamvu zochepa.

Table 3 mphamvu yakumeta ubweya wa 1Cr18Ni9Ti chitsulo chosapanga dzimbiri cholumikizana ndi malata otsogolera

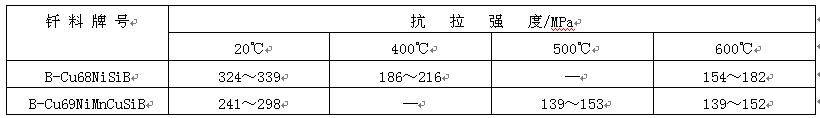

Silver based filler zitsulo ndizomwe zimagwiritsidwa ntchito kwambiri popangira zitsulo zosapanga dzimbiri.Mwa iwo, zinki zamkuwa zasiliva ndi zitsulo zamkuwa zamkuwa zinc cadmium filler zimagwiritsidwa ntchito kwambiri chifukwa kutentha kwa brazing sikukhudza kwambiri zitsulo zoyambira.Mphamvu za ICr18Ni9Ti zolumikizira zitsulo zosapanga dzimbiri zomangika ndi zida zingapo zasiliva zodziwika bwino zalembedwa mu Gulu 4. Zolumikizira zitsulo zosapanga dzimbiri zomangika ndi zida zasiliva sizimagwiritsidwa ntchito kawirikawiri pama media owononga kwambiri, ndipo kutentha kwamalo olumikizira nthawi zambiri sikudutsa 300 ℃. .Mukawotcha chitsulo chosapanga dzimbiri popanda faifi tambala, kuti mupewe dzimbiri zolumikizirana m'malo achinyezi, zitsulo zokhala ndi faifi tambala ziyenera kugwiritsidwa ntchito, monga b-ag50cuzncdni.Mukawotcha chitsulo chosapanga dzimbiri cha martensitic, kuti mupewe kufewetsa zitsulo zoyambira, zitsulo zodzaza ndi zitsulo zosapitirira 650 ℃ ziyenera kugwiritsidwa ntchito, monga b-ag40cuzncd.Mukawotcha chitsulo chosapanga dzimbiri mumlengalenga woteteza, kuti muchotse filimu ya oxide pamtunda, lithiamu yokhala ndi self brazing flux ingagwiritsidwe ntchito, monga b-ag92culi ndi b-ag72culi.Mukawotcha chitsulo chosapanga dzimbiri mu vacuum, kuti zitsulo zodzaza zizikhalabe ndi kunyowa kwabwino pomwe mulibe zinthu monga Zn ndi CD zomwe zimakhala zosavuta kusuntha, zitsulo zodzaza siliva zomwe zili ndi zinthu monga Mn, Ni ndi RD zitha kukhala. osankhidwa.

Table 4 mphamvu ya ICr18Ni9Ti chitsulo chosapanga dzimbiri cholumikizidwa ndi chitsulo chodzaza ndi siliva

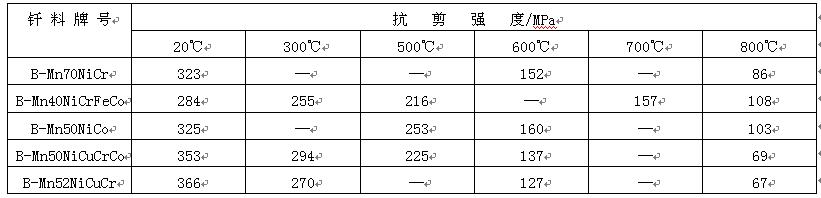

Zitsulo zodzaza ndi mkuwa zomwe zimagwiritsidwa ntchito pomanga zitsulo zosiyanasiyana zimakhala makamaka zamkuwa, faifi tambala wamkuwa ndi zitsulo zamkuwa za manganese cobalt brazing.Chitsulo choyera cha mkuwa chimagwiritsidwa ntchito kwambiri pobisala pansi pa chitetezo cha gasi kapena vacuum.Kutentha kogwira ntchito kwa olowa zitsulo zosapanga dzimbiri sikupitilira 400 ℃, koma olowa ali ndi kukana koyipa kwa okosijeni.Copper nickel brazing filler chitsulo chimagwiritsidwa ntchito makamaka pakuwotcha kwamoto komanso kuwotcha kwa induction.Mphamvu yachitsulo chosapanga dzimbiri cha 1Cr18Ni9Ti ikuwonetsedwa mu Table 5. Zitha kuwoneka kuti mgwirizanowu uli ndi mphamvu zofanana ndi zitsulo zoyambira, ndipo kutentha kwa ntchito kumakhala kwakukulu.Chitsulo cha Cu Mn co brazing filler chimagwiritsidwa ntchito makamaka pomanga chitsulo chosapanga dzimbiri cha martensitic mumlengalenga woteteza.Mphamvu yolumikizana ndi kutentha kwa ntchito ikufanana ndi yomwe imapangidwa ndi zitsulo zagolide.Mwachitsanzo, chitsulo chosapanga dzimbiri cha 1Cr13 chopangidwa ndi b-cu58mnco solder chimakhala ndi ntchito yofanana ndi chitsulo chosapanga dzimbiri chopangidwa ndi b-au82ni solder (onani Table 6), koma mtengo wopangira umachepetsedwa kwambiri.

Table 5 mphamvu yakumeta ubweya wa 1Cr18Ni9Ti chitsulo chosapanga dzimbiri cholumikizidwa ndi chitsulo chamkuwa chokwera kwambiri

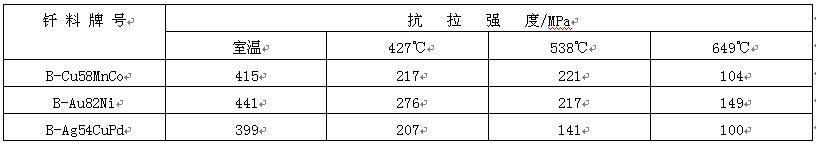

Gome 6 mphamvu yakumeta ubweya wa 1Cr13 chitsulo chosapanga dzimbiri cholumikizana

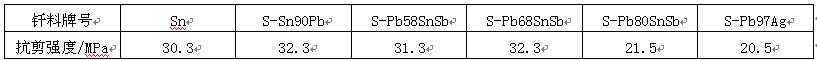

Manganese based brazing filler zitsulo zimagwiritsidwa ntchito kwambiri popangira mafuta otetezedwa ndi mpweya, ndipo kuyera kwa gasi kumafunika kukhala kokwezeka.Pofuna kupewa kukula kwa njere zachitsulo choyambira, chitsulo chofananira ndi brazing filler chokhala ndi kutentha kochepera kuposa 1150 ℃ chiyenera kusankhidwa.Zokhutiritsa zowonongeka zimatha kupezeka pazolumikizana zazitsulo zosapanga dzimbiri zopangidwa ndi solder ya manganese, monga momwe tawonetsera mu Table 7. Kutentha kogwira ntchito kwa olowa kumatha kufika 600 ℃.

Table 7 kukameta ubweya wa mphamvu ya lcr18ni9fi chitsulo chosapanga dzimbiri cholumikizidwa ndi manganese based filler chitsulo

Chitsulo chosapanga dzimbiri chikalumikizidwa ndi chitsulo cha nickel base filler, cholumikiziracho chimakhala ndi kutentha kwambiri.Chitsulo chofiyirachi nthawi zambiri chimagwiritsidwa ntchito popangira magetsi otchingidwa ndi gasi kapena vacuum brazing.Pofuna kuthana ndi vuto loti ma brittle compounds ambiri amapangidwa mu mgwirizano wa brazed panthawi yolumikizana, zomwe zimachepetsa kwambiri mphamvu ndi pulasitiki ya mgwirizano, kusiyana kwa mgwirizano kuyenera kuchepetsedwa kuonetsetsa kuti zinthu zosavuta kupanga brittle gawo mu mgwirizano. solder amasiyanitsidwa kwathunthu muzitsulo zoyambira.Pofuna kupewa kupezeka kwa maziko achitsulo kukula kwambewu chifukwa cha nthawi yayitali yogwira pa kutentha kwa kutentha, njira yogwiritsira ntchito nthawi yayitali ndi kufalitsa mankhwala pa kutentha kochepa (poyerekeza ndi kutentha kwa brazing) pambuyo pa kuwotcherera kungatengedwe.

Zitsulo zabwino kwambiri zopangira zitsulo zosapanga dzimbiri zimaphatikizanso zitsulo zopangidwa ndi golide ndi palladium yokhala ndi zitsulo zodzaza, zomwe zambiri ndi b-au82ni, b-ag54cupd ndi b-au82ni, zomwe zimanyowa bwino.Olowa brazed zosapanga dzimbiri ali mkulu kutentha mphamvu ndi makutidwe ndi okosijeni kukana, ndi pazipita ntchito kutentha akhoza kufika 800 ℃.B-ag54cupd ili ndi makhalidwe ofanana ndi b-au82ni ndipo mtengo wake ndi wotsika, choncho imakonda kusintha b-au82ni.

(2) Pamwamba pa chitsulo chosapanga dzimbiri mumlengalenga ndi ng'anjo imakhala ndi ma oxides monga Cr2O3 ndi TiO2, omwe amatha kuchotsedwa pogwiritsa ntchito flux ndi ntchito zamphamvu.Chitsulo chosapanga dzimbiri chikakulungidwa ndi solder ya malata, njira yoyenera ndi phosphoric acid aqueous solution kapena zinc oxide hydrochloric acid solution.Nthawi yogwira ntchito ya phosphoric acid yamadzimadzi ndi yochepa, kotero njira yowotchera yotentha yotentha iyenera kutengedwa.Fb102, fb103 kapena fb104 fluxes angagwiritsidwe ntchito pomanga zitsulo zosapanga dzimbiri ndi zitsulo zopangira siliva.Mukawotcha chitsulo chosapanga dzimbiri ndi chitsulo chodzaza ndi mkuwa, fb105 flux imagwiritsidwa ntchito chifukwa cha kutentha kwambiri.

Mukawotcha chitsulo chosapanga dzimbiri mu ng'anjo, mpweya wa vacuum kapena mlengalenga woteteza monga hydrogen, argon ndi kuwonongeka kwa ammonia nthawi zambiri amagwiritsidwa ntchito.Panthawi ya vacuum brazing, kuthamanga kwa vacuum kumakhala kotsika kuposa 10-2Pa.Mukawotchera m'malo oteteza, mame a gasi sadzakhala apamwamba kuposa -40 ℃ Ngati chiyero cha gasi sichikwanira kapena kutentha kwamoto sikuli kokwera, kutulutsa mpweya pang'ono, monga boron trifluoride, kumatha. iwonjezedwa mumlengalenga.

2. Zipangizo zamakono

Chitsulo chosapanga dzimbiri chiyenera kutsukidwa mosamalitsa musanawomedwe kuti muchotse filimu yamafuta ndi mafuta.Ndi bwino kuti braze mwamsanga pambuyo kuyeretsa.

Kuwotcha kwachitsulo chosapanga dzimbiri kumatha kugwiritsa ntchito njira zoyatsira moto, induction ndi ng'anjo yapakatikati.Ng'anjo yowotchera mu ng'anjoyo iyenera kukhala ndi njira yabwino yoyendetsera kutentha (kusiyana kwa kutentha kwa moto kumafunika kukhala ± 6 ℃) ndipo kumatha kukhazikika mwachangu.hydrogen ikagwiritsidwa ntchito ngati gasi wotchingira poyatsira moto, zofunika za hydrogen zimadalira kutentha kwa chitsulo ndi kapangidwe kachitsulo, ndiko kuti, kutsika kwa kutentha kwamoto, m'pamenenso zitsulo zoyambira zimakhala ndi stabilizer, ndipo mame amatsika. mfundo ya hydrogen ndiyofunika.Mwachitsanzo, pazitsulo zosapanga dzimbiri za martensitic monga 1Cr13 ndi cr17ni2t, zikamayaka pa 1000 ℃, mame a haidrojeni amafunika kukhala otsika kuposa -40 ℃;Kwa 18-8 chromium nickel chitsulo chosapanga dzimbiri popanda stabilizer, mame a haidrojeni azikhala otsika kuposa 25 ℃ pakuwotcha pa 1150 ℃;Komabe, chitsulo chosapanga dzimbiri cha 1Cr18Ni9Ti chokhala ndi titanium stabilizer, mame a haidrojeni ayenera kukhala otsika kuposa -40 ℃ akamayaka pa 1150 ℃.Mukabisala ndi chitetezo cha argon, chiyero cha argon chiyenera kukhala chapamwamba.Ngati mkuwa kapena faifi wapangidwa pamwamba pa chitsulo chosapanga dzimbiri, kufunikira kwa chiyero cha mpweya wotchinga kungachepe.Pofuna kuonetsetsa kuti filimu ya oxide imachotsedwa pamwamba pa chitsulo chosapanga dzimbiri, BF3 mpweya wotuluka ukhoza kuwonjezeredwa, ndipo lithiamu kapena boron yomwe ili ndi self flux solder ingagwiritsidwe ntchito.Pamene vacuum brazing chitsulo chosapanga dzimbiri, zofunikira za digiri ya vacuum zimatengera kutentha kwamoto.Ndi kuwonjezeka kwa kutentha kwa brazing, vacuum yofunikira imatha kuchepetsedwa.

Njira yayikulu yopangira chitsulo chosapanga dzimbiri pambuyo pakuwotcha ndikuyeretsa chotsalira chotsalira ndi choletsa chotsalira, ndikuchita chithandizo cha kutentha kwa post brazing ngati kuli kofunikira.Kutengera ndi njira ya flux ndi brazing yomwe imagwiritsidwa ntchito, madzi otsalira amatha kutsukidwa ndi madzi, kutsukidwa ndi makina kapena kutsukidwa ndi mankhwala.Ngati abrasive imagwiritsidwa ntchito kuyeretsa chotsalira chotsalira kapena filimu ya okusayidi pamalo otentha pafupi ndi olowa, mchenga kapena tinthu tating'ono tating'ono tazitsulo tating'ono tingagwiritsidwe ntchito.Zigawo zopangidwa ndi chitsulo chosapanga dzimbiri cha martensitic ndi mpweya wowumitsa zitsulo zosapanga dzimbiri zimafunikira chithandizo cha kutentha molingana ndi zofunikira zakuthupi pambuyo pakuwotcha.Zolumikizira zitsulo zosapanga dzimbiri zomangika ndi zitsulo za Ni Cr B ndi Ni Cr Si filler nthawi zambiri zimathandizidwa ndi kutentha kwapang'onopang'ono pambuyo pakuwotcha kuti muchepetse kufunikira kwa kusiyana kwa brazing ndikuwongolera ma microstructure ndi malo olumikizirana.

Nthawi yotumiza: Jun-13-2022