Kusintha kwa Superalloys

(1) Makhalidwe a brazing superalloys amatha kugawidwa m'magulu atatu: maziko a faifi tambala, maziko achitsulo ndi maziko a cobalt.Amakhala ndi zida zabwino zamakina, kukana kwa okosijeni komanso kukana kwa dzimbiri pakutentha kwambiri.Nickel base alloy ndi yomwe imagwiritsidwa ntchito kwambiri popanga.

Superalloy imakhala ndi Cr yambiri, ndi filimu ya Cr2O3 oxide yomwe imakhala yovuta kuchotsa imapangidwa pamwamba pa kutentha.Nickel base superalloys ali ndi Al ndi Ti, omwe ndi osavuta oxidize akatenthedwa.Choncho, kuteteza kapena kuchepetsa makutidwe ndi okosijeni wa superalloys pa kutentha ndi kuchotsa filimu okusayidi ndi vuto lalikulu pa brazing.Monga borax kapena boric acid mu flux angayambitse dzimbiri zitsulo m'munsi pa kutentha kwa brazing, boron inagwetsa pambuyo zimene akhoza kulowa mu zitsulo m'munsi, chifukwa intergranular kulowerera.Kwa ma aloyi a nickel base okhala ndi Al ndi Ti apamwamba kwambiri, kuchuluka kwa vacuum pakutentha sikuyenera kuchepera 10-2 ~ 10-3pa panthawi yowotcha kuti asatengeke ndi okosijeni pamtunda wa aloyi pakutentha.

Kuti njira yothetsera kulimbikitsana ndi mpweya kumalimbitsa ma aloyi a nickel base, kutentha kwamoto kuyenera kukhala kogwirizana ndi kutentha kwa kutentha kwa njira yothetsera kuonetsetsa kuti zinthu zonse za alloy zidzatha.Kutentha kwamoto kumakhala kochepa kwambiri, ndipo zinthu za alloy sizingathe kusungunuka;Ngati kutentha kwamoto kuli kwakukulu kwambiri, njere yachitsulo yoyambira idzakula, ndipo zinthu zakuthupi sizidzabwezeretsedwa ngakhale pambuyo pa chithandizo cha kutentha.Kutentha kolimba kwa ma cast base alloys ndikokwera, komwe sikungakhudze zinthu zakuthupi chifukwa cha kutentha kwambiri.

Ma nickel base superalloys, makamaka mvula yolimbitsa ma alloys, amakhala ndi chizolowezi chosweka mtima.Asanawombedwe, kupsinjika komwe kumapangidwa panthawiyi kuyenera kuchotsedwa kwathunthu, ndipo kupsinjika kwamafuta kuyenera kuchepetsedwa pakuwotcha.

(2) Brazing material nickel base alloy imatha kupangidwa ndi siliva, mkuwa weniweni, nickel base ndi solder yogwira.Pamene kutentha kwa ntchito ya olowa si mkulu, siliva zochokera zipangizo angagwiritsidwe ntchito.Pali mitundu yambiri ya ma solders asiliva.Pofuna kuchepetsa kupanikizika kwamkati mkati mwa kutentha kwa moto, ndi bwino kusankha solder ndi kutentha kochepa kusungunuka.Fb101 flux itha kugwiritsidwa ntchito pomanga ndi zitsulo zasiliva.Fb102 flux imagwiritsidwa ntchito popangira mvula yolimbitsa ma superalloy yokhala ndi aluminiyamu yapamwamba kwambiri, ndipo 10% ~ 20% sodium silicate kapena aluminium flux (monga fb201) imawonjezeredwa.Kutentha kwa brazing kupitilira 900 ℃, fb105 flux iyenera kusankhidwa.

Mukawotcha mu vacuum kapena mlengalenga woteteza, mkuwa weniweni ukhoza kugwiritsidwa ntchito ngati chitsulo chodzaza ndi brazing.Kutentha kwa brazing ndi 1100 ~ 1150 ℃, ndipo cholumikizira sichidzatulutsa kupsinjika, koma kutentha kwa ntchito sikudutsa 400 ℃.

Chitsulo cha Nickel base brazing filler ndiye chitsulo chomwe chimagwiritsidwa ntchito kwambiri ku Brazing filler ku Superalloys chifukwa chakuchita bwino kwa kutentha kwake komanso kulibe kusweka kwa nkhawa panthawi yowotcha.Zinthu zazikulu za alloy mu nickel base solder ndi Cr, Si, B, ndi solder pang'ono imakhalanso ndi Fe, W, ndi zina. B muzitsulo zoyambira ndikuwonjezera kutentha kwapakati.Ndi chitsulo chodzaza ndi brazing chowotcha mbali zotentha kwambiri komanso masamba a turbine.Komabe, fluidity ya W-muna solder kumakhala koipitsitsa ndipo kusiyana kwa mgwirizano kumakhala kovuta kulamulira.

Chitsulo chogwira ntchito cha brazing brazing filler sichikhala ndi Si element ndipo chimakhala ndi kukana kwa okosijeni kwabwino komanso kukana vulcanization.Kutentha kwa brazing kumatha kusankhidwa kuchokera ku 1150 ℃ mpaka 1218 ℃ malinga ndi mtundu wa solder.Pambuyo brazing, olowa brazed ndi katundu yemweyo monga zitsulo m'munsi angapezeke pambuyo 1066 ℃ mankhwala diffusion.

(3) Brazing process nickel base alloy imatha kutengera brazing mu ng'anjo yoteteza, vacuum brazing ndi kulumikizana kwamadzi kwakanthawi.Asanawombedwe, pamwamba pake ayenera kutsukidwa ndi okusayidi kuchotsedwa ndi kupukuta kwa sandpaper, kupukuta magudumu, kupukuta kwa acetone ndi kuyeretsa mankhwala.Posankha magawo opangira brazing, ziyenera kudziwidwa kuti kutentha kwa kutentha sikuyenera kukhala kokwera kwambiri ndipo nthawi yowotchera iyenera kukhala yochepa kuti tipewe kuchitapo kanthu kwamphamvu kwamankhwala pakati pa flux ndi chitsulo choyambira.Pofuna kupewa chitsulo choyambira kuti chisaphwanyike, zigawo zozizira zozizira ziyenera kuchepetsedwa musanayambe kuwotcherera, ndipo kutentha kwa kuwotcherera kumakhala kofanana momwe kungathekere.Pakuti mpweya kulimbitsa superalloys, mbali adzakhala pansi olimba njira mankhwala choyamba, ndiye brazed pa kutentha pang`ono kuposa ukalamba kulimbikitsa mankhwala, ndipo potsiriza ukalamba mankhwala.

1) Kuwotcha mu ng'anjo yodzitchinjiriza mu ng'anjo yoteteza kumafuna kuyeretsa kwakukulu kwa mpweya wotchinga.Kwa ma superalloys okhala ndi w (AL) ndi w (TI) osakwana 0.5%, mame amakhala otsika kuposa -54 ℃ akagwiritsidwa ntchito ndi haidrojeni kapena argon.Pamene zomwe zili mu Al ndi Ti zikuwonjezeka, alloy pamwamba imakhalabe oxidize ikatenthedwa.Njira zotsatirazi ziyenera kuchitidwa;Onjezerani pang'ono (monga fb105) ndikuchotsani filimu ya oxide ndi flux;0.025 ~ 0.038mm zokutira wandiweyani ndi yokutidwa pamwamba pa mbali;Uza solder pamwamba pa zinthu kuti brazed pasadakhale;Onjezerani pang'ono mpweya wotuluka, monga boron trifluoride.

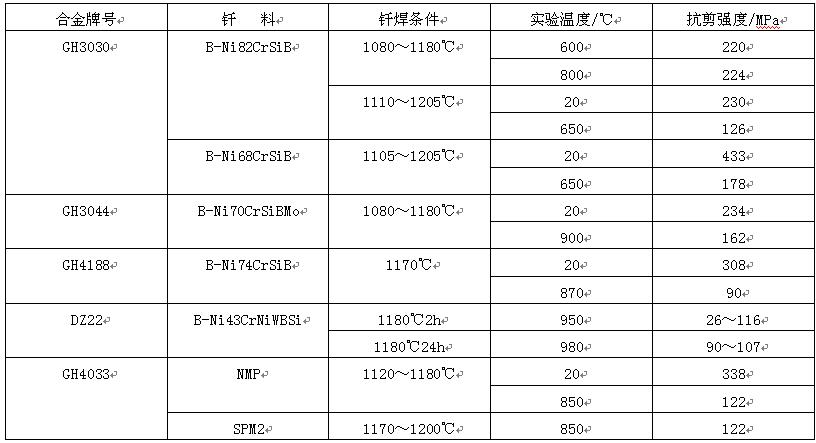

2) Vacuum brazing vacuum brazing amagwiritsidwa ntchito kwambiri kuti apeze chitetezo chabwino komanso mtundu wa brazing.Onani tebulo 15 la mawonekedwe a nickel base superalloy joints.Pakuti superalloys ndi w (AL) ndi w (TI) zosakwana 4%, ndi bwino electroplate wosanjikiza 0.01 ~ 0.015mm faifi tambala padziko, ngakhale wetting wa solder akhoza kuonetsetsa popanda pretreatment wapadera.Pamene w (AL) ndi w (TI) upambana 4%, makulidwe a nickel ❖ kuyanika adzakhala 0.020.03mm.Chophimba chochepa kwambiri sichikhala ndi chitetezo, ndipo kuyanika kwambiri kumachepetsa mphamvu ya mgwirizano.Zigawo zowotcherera zitha kuikidwanso mu bokosi la vacuum brazing.Bokosilo liyenera kudzazidwa ndi getter.Mwachitsanzo, Zr imatenga gasi kutentha kwambiri, komwe kumatha kupanga vacuum yapafupi m'bokosilo, motero kuletsa okosijeni pamtunda wa alloy.

Tebulo 15 zama makina a Vacuum Brazed Joints of wamba nickel base superalloys

Kusintha kwa microstructure ndi mphamvu ya mgwirizano wa brazed wa Superalloy ndi kusiyana kwa brazing, ndipo chithandizo cha kufalikira pambuyo pobowola chidzawonjezera phindu lalikulu lovomerezeka la kusiyana kwa mgwirizano.Kutenga aloyi ya Inconel mwachitsanzo, kusiyana kwakukulu kwa mgwirizano wa Inconel wopangidwa ndi b-ni82crsib ukhoza kufika 90um pambuyo pofalitsa mankhwala pa 1000 ℃ kwa 1H;Komabe, m'malo olumikizirana mafupa ndi b-ni71crsib, kusiyana kwakukulu kumakhala pafupifupi 50um pambuyo pa kufalikira kwa mankhwala pa 1000 ℃ kwa 1H.

3) Kulumikizana kwamadzimadzi kwakanthawi kochepa kumagwiritsa ntchito aloyi ya interlayer (pafupifupi 2.5 ~ 100um thick) yomwe malo ake osungunuka ndi otsika kuposa chitsulo choyambira ngati chitsulo chodzaza.Pansi pa kuthamanga yaing'ono (0 ~ 0.007mpa) ndi kutentha koyenera (1100 ~ 1250 ℃), interlayer chuma choyamba amasungunuka ndi moistens m'munsi zitsulo.Chifukwa cha kufalikira kofulumira kwa zinthu, kulimba kwa isothermal kumachitika pamgwirizano kuti apange mgwirizano.Njirayi imachepetsa kwambiri zofunikira zofananira zazitsulo zam'munsi komanso zimachepetsa kuthamanga kwa kuwotcherera.Waukulu magawo a chosakhalitsa madzi gawo kugwirizana ndi kuthamanga, kutentha, akugwira nthawi ndi zikuchokera interlayer.Ikani kupanikizika kochepa kuti mating pamwamba pa welds agwirizane bwino.Kutentha kwa kutentha ndi nthawi kumakhudza kwambiri ntchito ya olowa.Ngati olowa ayenera kukhala amphamvu ngati zitsulo m'munsi ndipo sizimakhudza ntchito ya zitsulo m'munsi, kugwirizana ndondomeko magawo kutentha (monga ≥ 1150 ℃) ndi nthawi yaitali (monga 8 ~ 24h) adzakhala kutengedwa;Ngati kugwirizana kwa olowa kumachepetsedwa kapena chitsulo choyambira sichingathe kupirira kutentha kwakukulu, kutentha kochepa (1100 ~ 1150 ℃) ndi nthawi yochepa (1 ~ 8h) idzagwiritsidwa ntchito.Wosanjikiza wapakatikati adzatenga cholumikizira m'munsi zitsulo zikuchokera monga zikuchokera, ndi kuwonjezera zinthu zosiyanasiyana kuzirala, monga B, Si, Mn, Nb, etc. Mwachitsanzo, zikuchokera Udimet aloyi ndi ni-15cr-18.5co-4.3 al-3.3ti-5mo, ndi zikuchokera wapakatikati wosanjikiza kwa chosakhalitsa madzi gawo kugwirizana ndi b-ni62.5cr15co15mo5b2.5.Zinthu zonsezi zimatha kuchepetsa kutentha kosungunuka kwa Ni Cr kapena Ni Cr Co alloys mpaka pansi, koma zotsatira za B ndizodziwikiratu.Komanso, mkulu mayamwidwe mlingo wa B akhoza mofulumira homogenize interlayer aloyi ndi m'munsi zitsulo.

Nthawi yotumiza: Jun-13-2022